Pioneering Rapid Casting for Conventional Rolls

HANI roll manufacturer completed the pouring of 8 rolls (Ø300–Ø400 mm) from a single 5-ton ladle in just 4 minutes and 50 seconds. This reduces pouring time by more than half compared to traditional methods and sets a new record for the fastest casting speed of metallurgical cast iron rolls in China.

Conventional roll pouring involves casting one roll at a time: after the initial pour, a thin stream of iron is added to the riser once the rotation of the molten iron stops to prevent neck shrinkage. The new rapid pouring method involves:

First pour for rolls 1–4, followed by a trickle top-up for the same set.

Second pour for rolls 5–8, again followed by trickle refilling.

This approach allows 4 rolls to be cast per cycle. The trickle refill is timed when the molten iron in the riser has nearly stopped rotating—the optimal moment for feeding. This eliminates waiting time between rolls and significantly shortens total pouring time. Key to this method is precise quantitative pouring, requiring highly accurate iron measurement to ensure complete filling in one go.

Rapid pouring greatly reduces temperature variation between rolls cast from the same ladle, minimizing defects such as porosity, slag inclusion, shrinkage cavities, and looseness in later-cast rolls. For nodular iron rolls, rapid pouring after spheroidization and inoculation reduces inoculation fade, ensures effective inoculation, and significantly improves tensile strength. Tests show that chromium-molybdenum and low-/medium-nickel nodular iron rolls produced by HANI exhibit tensile strengths in the range of 400–450 N/mm².

Introducing Wet-Lining Technology for 3t Medium-Frequency Electric Furnaces

HANI adopted wet-lining technology for its 3t medium-frequency electric furnace, achieving a furnace life exceeding 200 cycles and setting a new record of 275 cycles. Reaching such longevity under discontinuous smelting conditions represents a major advance.

The success of wet-lining construction challenges traditional dry-lining methods. This process involves adding a certain amount of water to the refractory material, removing the steel crucible mold after setting, pre-drying with firewood for several hours, and then beginning smelting. Compared to dry linings, the wet method saves one steel mold per rebuild, reduces oven-drying time by 25–28 hours, and saves approximately 2,500 kWh per oven-drying cycle. A new lining can be built and smelting started on the same day.

This method not substantially reduces relining cost but also increases furnace output. Over nearly ten years of use, the wet-lining approach has delivered significant economic benefits. Recent improvements include using tamping machines instead of manual compaction for better lining density and longer furnace life. Further innovation eliminated the pre-heating step, allowing direct charging after building the lining, saving both time and fuel. These enhancements enable same-day dismantling, relining, and furnace restart—a new industry benchmark.

Advancing Rapid Casting for Centrifugal Rolls

The company mainly produces small- and medium-sized centrifugal rolls with body diameters of Ø290–Ø400 mm, with a daily output of 20–26 rolls. The former method involved completely pouring one centrifugal roll (including outer layer and core filling) before starting the next—each taking about 15 minutes, allowing only 4 rolls per hour.

The new rapid method uses three centrifuges for continuous casting: after pouring the outer layer of the first roll, the outer layers of the second and third are poured consecutively, followed immediately by core filling for all three. This continuous process allows 6 centrifugal rolls to be cast in approximately 55 minutes, compared to 90 minutes with the old method—a 40% reduction in pouring time.

Besides improving productivity by 40%, this method shortens the residence time of molten iron in the furnace, minimizing carbon and silicon loss, stabilizing chemical composition, and reducing power consumption.

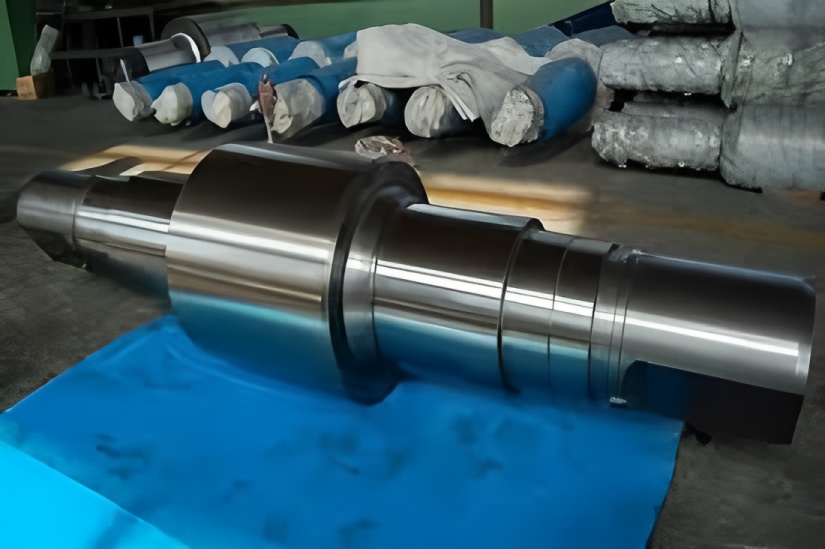

Applying Advanced Technology to Achieve Leading Strength in Centrifugal Rolls

Using advanced inoculation technology and adjusted chemical composition, HANI has achieved a tensile strength of 550–650 N/mm² in the roll necks of centrifugal rolls, with a peak of 670 N/mm²—setting a leading standard in China.

When the inner layer of a centrifugal roll is nodular cast iron, core inoculation typically uses either a single (in-ladle) or double (in-ladle + in-stream) process.

Earlier single inoculation methods often resulted in poor outcomes due to high pre-inoculation silicon content and low post-inoculation ferrosilicon addition (<0.4%). High chromium content (0.30–0.50%) in the core iron without corrective measures further led to issues such as coarse and irregular graphite, and sometimes cementite networks in the core structure. This resulted in low roll neck tensile strength (around 400 N/mm²) and occasional roll breakage.

Since 2006, a standardized double inoculation process (in-ladle + in-stream) has been implemented. This requires adding 0.50–0.80% ferrosilicon during ladle inoculation and 0.10–0.20% during pouring. The allowable final silicon content in the core iron has been raised from 2.50% to 2.80%. Practice confirms that even with Si content of 2.51–2.80%, roll neck tensile strength can reach 530–630 N/mm².

Since adopting this process, HANI has produced nearly 13,000 tons of small- and medium-sized centrifugal rolls (approx. 26,000 rolls) by June 2010, with no roll breakages due to quality issues, delivering significant economic benefits.