High-speed steel (HSS) rolls have emerged as a transformative innovation in modern rolling mill operations, offering unparalleled wear resistance, thermal stability, and surface integrity compared to conventional roll materials like chilled cast iron or high-chromium iron. Despite their superior performance, the processing of HSS rolls remains technically demanding due to their extreme hardness and complex carbide microstructure. This article provides a comprehensive, production-oriented guide to the machining, application, and operational best practices for HSS rolls—essential knowledge for mill roll specialists, roll shop engineers, and steel mill procurement teams.

Why High-Speed Steel Rolls? Material Science Behind the Performance

High-speed steel rolls are alloyed with significant concentrations of vanadium (V), molybdenum (Mo), tungsten (W), and chromium (Cr)—typically totaling 15–25% by weight. These elements form hard, thermally stable carbides, primarily of the MC (e.g., VC, NbC) and M₂C (e.g., Mo₂C, W₂C) types, which remain intact even at rolling temperatures exceeding 600°C. Unlike traditional roll materials that soften under thermal cycling, HSS rolls maintain a surface hardness of 60–68 HRC throughout the working layer due to their high hardenability.

Key metallurgical advantages include:

- Uniform hardness profile: Minimal drop (<5 HRC) from surface to core ensures consistent wear behavior.

- Self-forming oxide film: Under proper cooling, a dense Fe–Cr–V oxide layer forms, reducing adhesive wear and pick-up.

- Controlled thermal expansion: High coefficient of thermal expansion (~12 × 10⁻⁶/°C) enables “self-crowning,” maintaining pass geometry during hot rolling.

- Excellent fatigue resistance: Resists spalling and thermal cracking under cyclic loading in continuous mills.

Machining Challenges and Advanced Processing Technologies

Machining HSS rolls is notoriously difficult due to their abrasive carbide network and low thermal conductivity. Conventional carbide tools suffer rapid flank wear and edge chipping, leading to poor surface finish and dimensional inaccuracies. The solution lies in superabrasive tooling and optimized CNC strategies.

Tool Material Selection: CBN Dominates

Cubic boron nitride (CBN) is the industry-standard cutting material for HSS roll finishing. With a hardness second only to diamond (≈4500 HV) and thermal stability up to 1400°C, CBN outperforms polycrystalline diamond (PCD)—which reacts chemically with ferrous alloys at high temperatures.

Two primary CBN tool configurations are used:

- Full CBN compacts: High CBN content (≥90%) with ceramic binders (e.g., AlN–TiN); ideal for roughing.

- CBN-tipped inserts: Thin CBN layer (0.5–1.0 mm) brazed onto tungsten carbide substrate; cost-effective for finishing.

Grades such as MBN3500 (medium grain, 70% CBN) and MBN5000 (ultra-fine grain, 85% CBN) are widely adopted in roll shops for their balance of toughness and wear resistance.

Optimized Machining Parameters for Grooved Rolls

For grooved HSS work rolls (e.g., in bar or wire rod mills), a hybrid machining approach maximizes efficiency:

| Operation Stage | Cutting Tool | Depth of Cut (mm) | Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|---|---|---|

| Rough Turning (Pre-groove) | Carbide (ISO K20) | 3.0–5.0 | 40–50 | 0.6–0.8 |

| Groove Roughing | CBN (MBN3500) | 1.5–2.0 | 60–70 | 0.4–0.5 |

| Groove Finishing (Arc) | CBN (MBN5000) | 0.3–0.4 | 70–80 | 0.3–0.4 |

| Base Circle Finishing | CBN (MBN5000) | 0.2–0.3 | 75–85 | 0.8 |

Pro tip: Pre-cut grooves using a narrow blade slightly undersized relative to the base circle to reduce radial cutting forces. Finish chamfers with a pointed cylindrical tool before switching to arc-shaped CBN inserts—this prevents edge chipping and ensures precise fillet radii.

Application Best Practices in Hot and Cold Rolling Mills

HSS rolls are now standard in Japanese and European mills for both hot and cold applications—from plate mills to high-speed wire rod lines. Their adoption in China began in the mid-1990s with narrow hot-strip mills and has since expanded to continuous casting–rolling integrated lines.

Cooling System Requirements

Inadequate cooling is the leading cause of premature HSS roll failure. Thermal shock induces microcracks, while insufficient flow leads to carbide decomposition and softening. Critical parameters:

- Water temperature: ≤40°C (ideally 25–35°C)

- Pressure: 0.4–0.6 MPa

- Flow rate: ≥300 L/min per roll (500+ L/min for large backup rolls)

- Nozzle design: Multiple annular rings with full circumferential coverage

- Flow distribution: 70–80% directed to the exit side (higher heat load)

Always activate cooling water before hot steel contacts the roll surface. In case of cobble or jamming, maintain water flow until both roll and scrap cool below 150°C to avoid phase transformation in the surface layer.

Performance Gains in Real-World Operations

Compared to high-chromium iron rolls, HSS rolls deliver:

- 2× longer campaign life in bar mills (e.g., 12,000 tons vs. 6,000 tons per groove)

- 30–50% reduction in roll changes, boosting mill availability by 3–5%

- Superior surface quality: fewer scratches, pits, and roll marks on finished products

- Stable dimensional control enabling tighter tolerance rolling (e.g., ±0.15 mm on rebar)

These benefits translate directly into higher throughput, lower maintenance costs, and enhanced product competitiveness—especially critical in markets demanding high-surface-quality cold-rolled sheet or precision-engineered long products.

Future Outlook and Strategic Recommendations

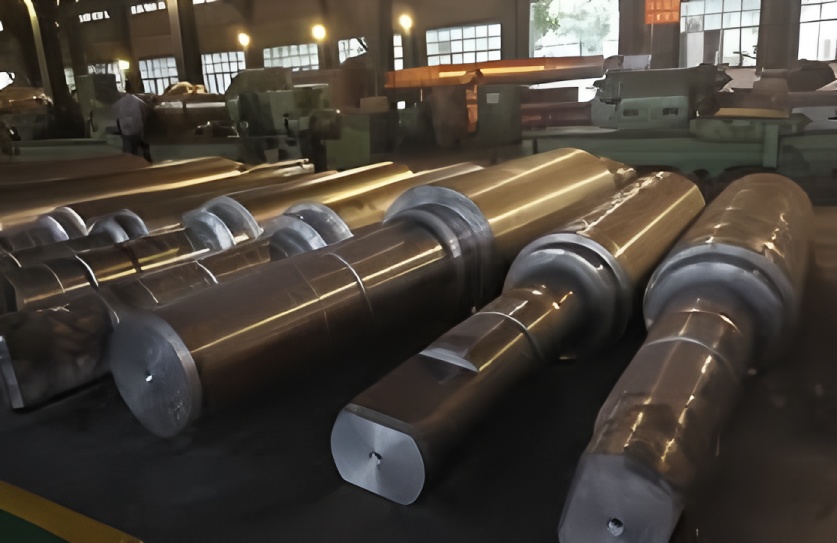

While initial investment in CBN tooling and rigid CNC lathes (e.g., CK84 series) is substantial, the ROI from extended roll life and reduced downtime justifies adoption. Leading manufacturers like HANI Roll Manufacturing Factory—holder of multiple Chinese national invention patents for centrifugally cast HSS rolls—now supply rolls up to 1,800 mm in diameter for hot strip backup applications.

For mill operators considering HSS roll implementation:

- Start with work rolls in less critical stands (e.g., finishing train of bar mills).

- Partner with roll suppliers offering full technical support—including grinding protocols and cooling audits.

- Train roll shop personnel on CBN tool handling and parameter optimization.

- Monitor roll surface temperature via infrared sensors to validate cooling efficacy.

As steel grades become stronger and rolling speeds increase, the demand for advanced roll materials will only grow. High-speed steel rolls, once a niche solution, are now a cornerstone of high-efficiency, high-quality rolling mill operations worldwide.

For mill roll manufacturers, roll grinding service providers, and steel producers seeking reliable HSS roll solutions, partnering with specialized foundries equipped with centrifugal casting capabilities and CNC roll lathes is essential to unlock maximum performance and longevity.