Correct Selection of Mill Rolls to Meet Production Requirements?

Optimal mill roll selection balances material, thermal stability, and mechanical demands across bar, wire rod, and section mills to ensure quality, productivity, and cost efficiency.

We can provide special services and differentiated mill rolls products according to the different conditions of the rolling mill.

Elevate the quality of your steel products with HANI’s top – notch Straightening Rollers. Engineered to perfection, these rollers deliver unmatched precision in eliminating bend, twist, and wave defects in steel sheets, bars, and tubes. Their advanced design and high – quality materials ensure consistent and reliable straightening performance, resulting in flawless steel products that meet the most stringent industry standards. Whether you’re in the automotive, construction, or manufacturing sector, HANI’s straightening rollers are your key to achieving superior product quality and customer satisfaction.

HANI is a company specialized in mill rolls production and supply. With many years of experience and advanced production equipment, we can provide you with high-quality and reliable mill roll products.

Our rolling mill rolls are suitable for various metallurgical industry fields, including the production of bars, wire rods, section steel, strips, etc. We can customize rolls according to customers’ specific requirements and application scenarios to ensure their performance and life in various environments.

HANI specializes in mill rolls grinding services. It has done so for over 30 years. We get you back up and running faster with our unmatched expertise and proprietary technology. The world No. 1 in crude steel production steel plant, over 70% of the MILL ROLLS for bar and wire are from us.

HANI mill rolls are made of high-quality materials, which can ensure the production of high-precision and high-quality finished products, Increased roll life means fewer regrinding cost, less roll changes and decreased downtime.

QUALITY

GET YOUR MILL ROLLS SAFETY STAY UP AND RUNNING LONGER

Our rolls passed the IS09001:2008 quality management system certification. With HANI, you won’t have performance problems, experience product consistency issues or run slower.

SAVINGS

GET YOUR MILL ROLLS FASTER AVOID EXPENSIVE DOWNTIME

We have overseas warehouses in the United States, Germany, India, Turkey, Mexico, we can receive and deliver your rolls faster, reducing costly downtime. Our mill rolls will run longer and better, saving you money in the process too.

VALUE

GET YOUR MILL ROLLS PRODUCE A BETTER PRODUCT FOR A LONGER TIME

High-speed steel rolls developed by HANI the amount of steel passing in a single groove (times) is 3 to 5 times that of cast iron rolls.

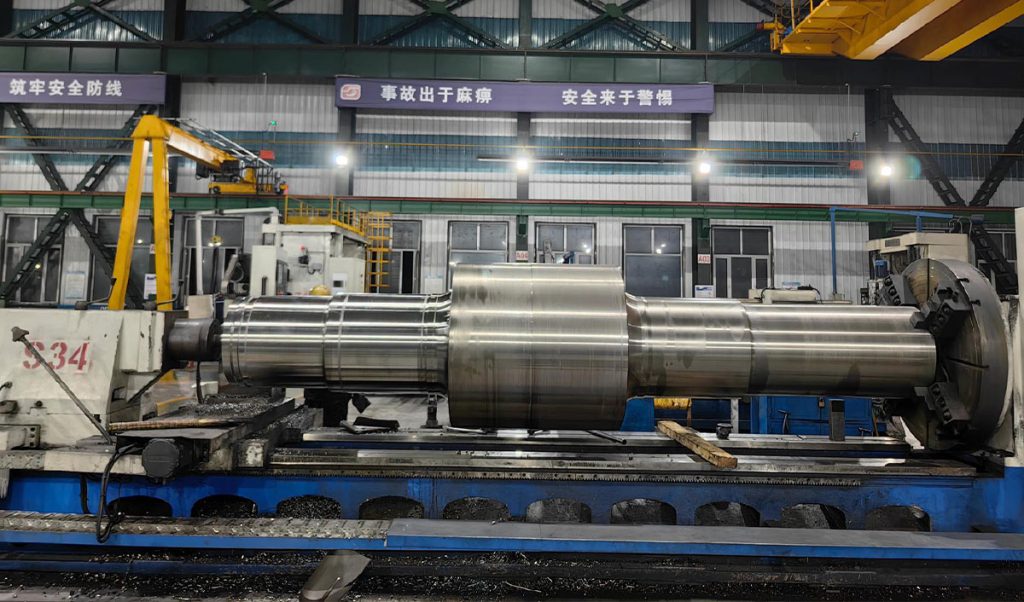

Cast rolls technical Process:

Modeling → smelting → centrifugal casting → cleaning → preliminary heat treatment → rough machining → differential heat treatment → finishing → packaging and delivery.

Technical excellence in our core competencies – melting, casting, forging, heat treating and machining – allows us to provide a superior product and meet the most demanding requirements of our customers.

The company strictly according to modern enterprise management requirements set up a perfectquality assurance system, and passed the ISO9001:2008 quality management system certification,ISO14001:2004 environmental management system certification, OHSAS18001:1999 occupationalhealth and safety management system certification.

With a globalized market strategy, info-driven marketing, and rapid, precise responses, HANI Group strengthens its market stance. Our mill rolls and other metallurgical products reach over 90 countries, with branches in the US, Switzerland, Middle East, Southeast Asia, Africa,and beyond. Focused on steelmaking, HANI boasts rich industry experience, with offices worldwide for enhanced customer service. Specializing in R&D, design, and manufacturing, our mill rolls excel. In 2020, we opened a new Fujian base, underscoring our global commitment.

Classification Based on Rolling Temperature

Classification Based on the Shape of Rolled Products

Rolled products are categorized according to their shapes, with corresponding rolls designed for each type. For instance, rolls used for producing hot-rolled strip products are known as hot strip rolls. Similarly, there are various other types, including cold strip rolls, plate steel rolls, section steel rolls, seamless steel tube rolls, and rod and wire rolls, each tailored to the specific shape and requirements of the rolled product.

Classification Based on the Function or Position of Rolling Mills Along the Rolling Line

Rolls are categorized by their roles or positions in the rolling process. Examples include blanking rolls for initial material cutting, roughing rolls for preliminary shaping, intermediate rolls, pre-finishing rolls, and finishing rolls for final surface quality.

Specialized rolls include cross-cut skinning rolls (for surface defect removal), slitting rolls (for strip division), edge rolling rolls (for edge shaping), piercing rolls (for tube production), and straightening rolls (for shape correction).

Classification Based on Roll Position in the Rolling Mill

Classification Based on Mill Roll Material

Based on material composition, rolls can be categorized into four primary types: cast steel rolls, cast iron rolls, forged steel rolls, and powder metallurgy rolls. These categories are further subdivided according to the specific material and principal alloying elements used in the working parts of the rolls, ensuring tailored performance for diverse rolling applications.

Mill Rolls Technology Forum

Optimal mill roll selection balances material, thermal stability, and mechanical demands across bar, wire rod, and section mills to ensure quality, productivity, and cost efficiency.

Precision welding overlay techniques for extending mill roll life—covering surface prep, preheating, SAW parameters, buffer layers, and post-weld cooling.

All contents of this website are copyrighted by HANI GROUP and may not be reproduced in any form without permission.

We would be happy to help and advise if you have any questions or inquiries.