PRE-INSTALLATION PREPARATION

Roller Inspection

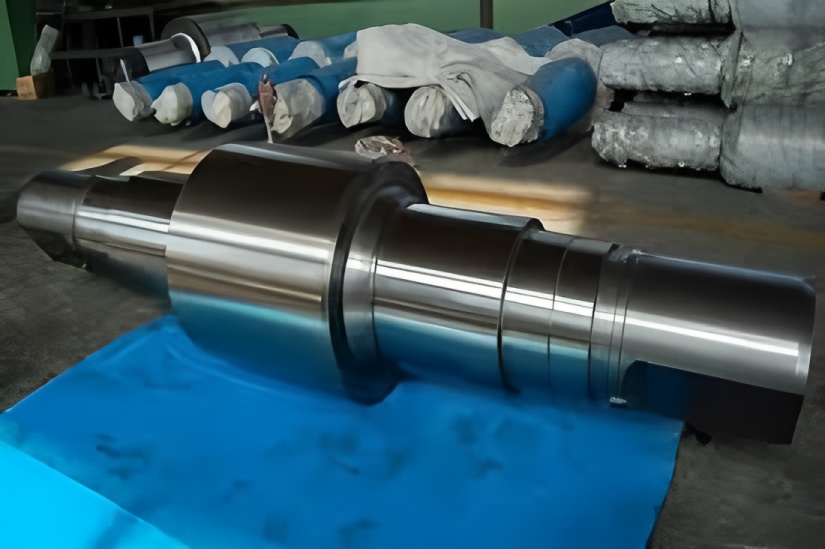

Examine roller surfaces for defects including bumps, scratches, and pitting

Address surface imperfections that could transfer to finished products

Verify neck dimensions and surface roughness meet specifications

Ensure proper fit with bearings and other components

Example: Deep scratches require remediation before installation

Parameter Verification

Confirm roll dimensions (diameter, length) match mill specifications

Ensure proper rolling force distribution and thickness control

Verify material composition and hardness requirements

Select appropriate roll grades for specific processes

Example: Higher hardness rolls for cold-rolled thin sheet production

INSTALLATION PROCEDURES

Cleaning Protocol

Thoroughly clean mill mounting surfaces and roll bodies

Remove oil stains, metal chips, and other contaminants

Prevent foreign material ingress in bearings and mating surfaces

Bearing and Seal Installation

Follow equipment manuals for proper bearing installation

Utilize heating methods for precision fits when required

Achieve micron-level accuracy in high-precision applications

Install seals using appropriate compounds and sequences

Ensure effective lubricant retention and contamination exclusion

Positioning and Alignment

Use proper lifting equipment for roll placement

Maintain horizontal and vertical alignment during installation

Verify alignment using precision levels and instruments

Tighten connecting bolts to specified torque values

Prevent operational loosening and maintain positioning

OPERATIONAL GUIDELINES

Lubrication Management

Select lubricants based on operational speed and load conditions

Implement scheduled lubrication intervals and quantities

Example: Regular lubrication in continuous production environments

Utilize high-quality synthetic lubricants for high-speed applications

Parameter Adjustment

Adjust rolling forces according to material specifications

Consider thickness, width, and material characteristics

Avoid exceeding roll load capacities

Maintain proper strip tension for stable operation

Example: Tension control for aluminum strip flatness

Operational Monitoring

Utilize sensor systems for real-time performance tracking

Monitor vibration, temperature, and speed parameters

Address temperature anomalies indicating lubrication issues

Observe strip quality for roll performance indicators

Example: Identify roll wear through dimensional variations

MAINTENANCE PROTOCOLS

Regular Inspection

Conduct comprehensive roll surface examinations

Assess bearing wear and clearance conditions

Verify seal effectiveness and connection integrity

Example: Scheduled inspections after specified production volumes

Repair and Replacement

Employ turning and grinding for minor surface restoration

Achieve required dimensional accuracy and surface finish

Replace severely damaged rolls when repair is impractical

Implement proper storage or disposal for replaced components

Example: Precision grinding for localized wear patterns