This article categorizes rolls based on various criteria, explains rolls made from different materials, and analyzes their applications both domestically and internationally.

Keywords: roll; classification; material selection

To meet the practical demands of steel rolling production, China needs to import a significant number of high-end rolls annually, expending considerable foreign exchange. Each year, approximately 30,000 tons of high-end rolls are imported, costing about USD 200 million. Currently, China’s roll consumption stands at 1.0 kg to 1.2 kg per ton of steel produced, with annual consumption of hot and cold rolls exceeding 900,000 tons, valued at over RMB 15 billion. This high level of consumption leads to substantial waste of resources and energy. Therefore, improving roll quality and extending service life can not only save roll materials and reduce resource consumption and environmental pollution but also conserve significant foreign exchange. Continuous research and development of new composite roll manufacturing technologies and equipment—featuring simple processes, high production efficiency, and low investment—to achieve low-cost, high-performance roll production and develop even higher-performance composite rolls represents the future direction of roll technology.

Classification of Rolls

There are many types of rolls, and classification methods vary, but they are generally categorized according to the following three criteria:

A. Classification by Usage:

Primary Rolling Rolls

Blooming mill rolls for slabs

Blooming mill rolls for billets (both are being phased out with increased continuous casting)

Strip Rolls

Plate rolls

Thin plate rolls

Hot-rolled strip rolls

Narrow strip rolls

Cold-rolled strip rolls

Section Steel Rolls

B. Classification by Material:

Cast Iron Rolls

Chilled cast iron rolls

Indefinite chilled cast iron rolls

Semi-chilled cast iron rolls

Nodular cast iron rolls

High chromium cast iron rolls

Cast Steel Rolls

Alloy cast steel rolls

Alloy semi-steel rolls

Graphite steel rolls

High chromium steel rolls

High-speed steel rolls

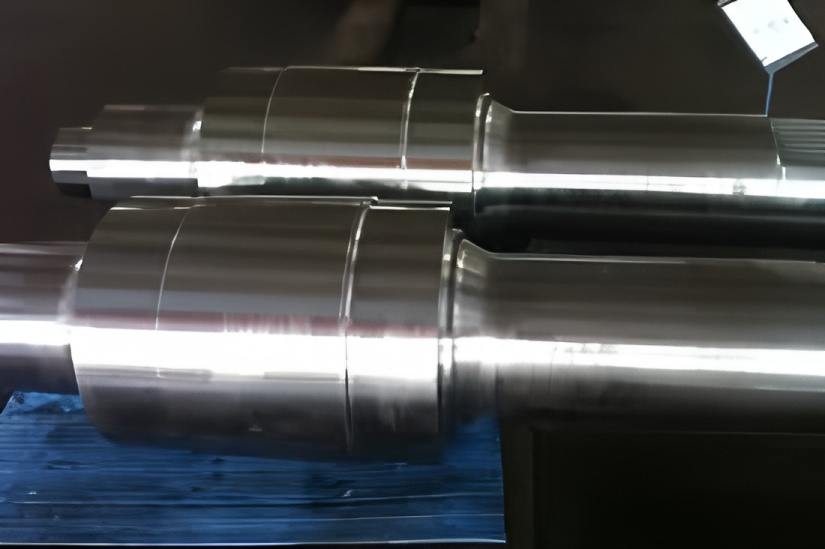

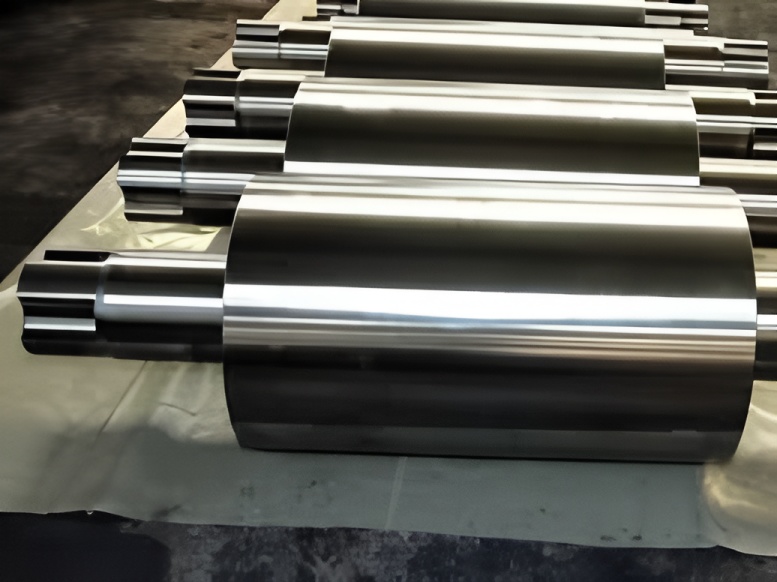

Forged Steel Rolls

Alloy forged steel rolls

High chromium forged steel rolls

Forged high-speed steel rolls

Special Rolls

Tungsten carbide rolls

Ceramic steel rolls

C. Classification by Weight:

Large rolls: over 10 tons

Medium rolls: 3–10 tons

Small rolls: under 3 tons

Selection of Roll Materials

Rolls are critical consumable tools in steel rolling production, directly affecting the dimensional accuracy and surface quality of the rolled product. Due to variations in rolling mill conditions, product types, and specifications, correct design of roll characteristics and appropriate material selection are essential.

Blooming Mill Rolls

Blooming mills are mainly divided into slab mills and billet mills. They use steel ingots with coarse dendritic structures prone to segregation. To eliminate the cast structure, high rolling temperatures and large deformations are applied to refine the grains. The roughing mill operates with high reduction rates and torque, making thermal crack resistance and strength key for these rolls.

Before the 1950s, most blooming mills abroad used forged steel rolls, later partly replaced by cast steel rolls. Although strong, these rolls lacked wear resistance and thermal crack resistance, often failing due to ring cracks. The introduction of nodular cast iron rolls in blooming mills was a breakthrough. In 1958, China became the first to use nodular iron rolls in blooming mills, achieving satisfactory results and expanding the application of nodular cast iron. Traditional cast steel rolls had a hardness of 27–35 HSD, while alloy nodular iron rolls reach 43–48 HSD, offering better wear and thermal crack resistance, though they are more prone to slipping. With good nodularization and heat treatment, strength is assured.

Plate Rolls

Plate mills include two-high reversible mills, three-high Lauth mills, and four-high reversible mills, which can be single-stand, double-stand, or multi-stand setups for semi-continuous or continuous rolling.

In three-high Lauth mills, the middle roll is the work roll, while the upper and lower rolls serve as both backup and work rolls. These rolls require good wear resistance, heat resistance, spalling resistance, and fracture resistance. Low or medium nickel-chromium-molybdenum indefinite chilled cast iron rolls with a surface hardness of 60–70 HSD are typically used.

The four-high reversible mill is widely used for medium and heavy plates, combining the advantages of two-high and three-high mills by reducing rolling pressure and increasing mill stiffness. Backup rolls are usually cast steel with a hardness of 45–52 HSD. Work rolls for finishing stands have evolved; in the 1950s, foreign mills used fully flushed high-alloy indefinite chilled cast iron rolls with a hardness of 75–82 HSD. This material is still used today, with improvements in graphite and carbide morphology. Leveling rolls use centrifugal composite high-alloy indefinite chilled cast iron with a hardness of 70–80 HSD.

Sheet Rolling Rolls

Although mostly phased out globally, several dozen stacked sheet rolling mills remain in China. These mills feature:

Irreversible cyclic rolling with long idle times.

Fast heat dissipation due to thin sheets and large surface area, often requiring reheating.

Multi-sheet stacking for thicknesses below 2 mm, typically rolling 0.28–4.0 mm.

No water cooling for rolls, which operate at 500–600°C.

Preheating and ironing of rolls before use at 380–420°C.

High rolling pressure, often over 900 tons, up to 1600 tons.

Given these harsh conditions, rolls require good thermal conductivity, spalling resistance, impact resistance, and fracture toughness. Low-alloy CrMo indefinite chilled nodular composite cast iron rolls with a hardness of 57–63 HSD are typically used. Common issues are roll breakage and spalling.

Hot-Rolled Strip Rolls

Hot-rolled strip mills include semi-continuous, 3/4 continuous, full continuous, and thin-slab continuous rolling. Roughing rolls must resist twisting, bending, and thermal cracking, often made of monolithic cast alloy cast steel (43–50 HSD) or high-strength alloy nodular iron (55–60 HSD). Some foreign manufacturers use composite cast steel rolls with a graphite steel outer layer with good results.

In continuous mills, backup rolls prevent work roll breakage. In the 1960s–70s, roughing stands used nickel-chromium-molybdenum indefinite chilled composite cast iron or semi-steel rolls (50–55 HSD). In the 1980s, Europe adopted high-chromium composite cast iron rolls (70–75 HSD). In the 1990s, semi-high-speed steel rolls were successfully applied in roughing stands due to high wear resistance, thermal crack resistance, spalling resistance, and bite performance.

The finishing mill consists of 5–7 stands. Backup rolls, usually cast steel (40–50 HSD) or forged steel (60–70 HSD), require good fatigue strength and fracture resistance. Work rolls in the early finishing stands (F1–F3) shifted in the 1980s to high-chromium composite cast iron rolls (70–80 HSD) to address roll sticking and oxide buildup. Where cooling water is insufficient or poor, severe spalling can occur. High-speed steel rolls, offering three times the service life, have now largely replaced high-chromium iron rolls in early finishing. Selection should be tailored to specific mill conditions.

Work rolls in later finishing stands (F4–F7) require high hardness, wear resistance, thermal crack resistance, and spalling resistance. Globally, these are typically made of high-nickel-chromium-molybdenum indefinite chilled composite cast iron rolls (75–85 HSD), prized for excellent wear resistance ensuring strip dimensional accuracy and surface finish. With material advances, high-speed steel rolls have shown remarkable results, extending roll change cycles 3–5 times with hardness reaching 80–90 HSD. Currently, high-speed steel rolls are common in F1–F5, while F6 and F7 often use improved high-nickel-chromium-molybdenum indefinite chilled cast iron (78–83 HSD). Leveling rolls use centrifugal composite high-alloy indefinite chilled cast iron (70–80 HSD).

Hot-Rolled Narrow Strip Rolls

Narrow strip steel, under 500 mm wide, uses mills similar to hot strip continuous mills. Roughing stands typically use alloy cast steel (40–50 HSD) or alloy nodular iron (45–55 HSD). Early finishing stands use bainitic nodular iron (60–70 HSD) or medium-high alloy indefinite chilled cast iron; later stands use high-alloy indefinite chilled cast iron (75–85 HSD) or high-speed steel (80–90 HSD). Semi-steel rolls are preferred for backup rolls.

Cold-Rolled Strip Rolls

Cold strip tandem mills have 3–6 stands of four-high mills with large backup rolls and small work rolls. Emulsified oil lubricates and cools the strip. Work rolls are forged steel (80–95 HSD); some mills use high-alloy indefinite chilled cast iron (75–80 HSD) for better shape control but risk graphite-induced strip contamination. Recently, semi-high-speed steel and high-chromium forged steel rolls have been breakthroughs for cold work rolls.

Large Section Steel Rolls

Large section mills have roughing, intermediate, and finishing stands, each requiring different materials.

Roughing stands have deep grooves, high temperatures, and pressures, requiring high strength and heat resistance. Foreign manufacturers often use nickel-chromium-molybdenum alloy cast steel or graphite steel rolls. Some now use alloy semi-steel (45–50 HSD) for better surface quality, effective if roll temperature is kept below 60°C.

Intermediate stands need good thermal crack resistance and wear resistance, often using alloy nodular iron (50–60 HSD) or cast alloy nodular iron with grooves.

Finishing stands ensure negative tolerance rolling and dimensional accuracy, requiring strength and excellent wear resistance. Pearlitic nodular iron or high-carbon semi-steel rolls are typical.

Medium and Small Section Steel Rolls

These are divided into roughing, intermediate, and finishing stands; material selection depends on mill type, product specs, and stand count.

Roughing stands with deep grooves require high strength and thermal crack resistance, often using alloy semi-steel or high-strength alloy nodular iron.

Intermediate stands endure heavy loads, needing good thermal crack resistance and some wear resistance. Alloy nodular iron or indefinite chilled cast iron rolls are common.

Finishing stands have lower pressure but require high wear resistance for dimensional accuracy. Pearlitic nodular iron, bainitic nodular iron, or nickel-chromium-molybdenum indefinite chilled cast iron (65–75 HSD) are used.

Bar Rolls

Bar mills are small section mills. By end-2003, China had introduced or built 118 bar continuous rolling mills. Rolls require good wear resistance, strength, thermal crack resistance, and toughness due to long heating times and material length.

Roughing stands endure high pressure, deep grooves, and large reduction, requiring high strength, thermal crack resistance, spalling resistance, wear resistance, impact resistance, and bite. These properties can conflict. Steel rolls offer better bite and strength but less wear and thermal crack resistance than nodular iron. Some use semi-steel, but thermal cracking is severe. Most now use ferritic nodular iron (45–50 HSD) for the first stand and pearlitic nodular iron (50–55 HSD) for others. The ideal material is non-carbide bainite rolls (NCC, 48–55 HSD), with high wear resistance and thermal crack propagation resistance but higher cost.

Intermediate stands have deep grooves and high pressure, so strength remains crucial. Inadequate groove cooling requires good thermal crack resistance and impact toughness. Wear resistance is higher, with groove bottom hardness similar to top. Pearlitic nodular iron (60–68 HSD) is ideal and economical. Acicular bainite nodular iron has better wear but slightly worse thermal crack resistance. Future trends favor semi-high-speed steel (68–75 HSD) with twice the wear resistance.

Finishing stands must ensure mill uptime, reduce roll changes, increase output, and guarantee surface quality. Wear resistance is key, along with toughness and spalling resistance. Acicular bainite nodular iron (68–75 HSD) is common. Recently, high-speed steel and tungsten carbide roll rings have gained popularity for their excellent wear resistance—3–5 times and 5–10 times that of bainite nodular iron, respectively. High-speed steel is cost-effective at one-tenth the price of carbide, indicating a shift toward value over initial cost.

High-Speed Wire Rod Rolls

High-speed wire rod mills have roughing, intermediate, finishing, and 2–4 pre-finishing stands. Roughing stands (4–8 stands) require breakage resistance, thermal cracking resistance, wear resistance, and bite. Pearlitic nodular iron (50–60 HSD) or alloy semi-steel (45–55 HSD) are typical.

Intermediate stands need good wear resistance and surface roughness resistance, often using pearlitic or bainitic nodular iron (60–70 HSD). Some use indefinite chilled rolls depending on mill conditions.

Pre-finishing stands reduce finishing accidents and improve dimensional accuracy. Rolls should bridge previous and future stands, emphasizing wear resistance. Increasing hard carbides in the matrix is effective. Pre-finishing rolls are often composite—roll ring and mandrel. Foreign roll rings use materials like high-hardness acicular iron, high-chromium iron, high-vanadium iron, high-tungsten-chromium iron, or tungsten carbide. In China, high-nickel-chromium-molybdenum indefinite chilled cast iron (75–80 HSD) with alloy nodular iron inner layers is common. Tungsten carbide offers good wear but low strength and frequent breakage. High-speed steel roll rings, with three times the wear resistance of high-nickel-chromium-molybdenum iron and higher strength than carbide, are more suitable.

Finishing stands require tungsten carbide roll rings (82–90 HSD) to ensure high-speed rolling and wear resistance. No other material currently replaces carbide here.

Gap in Bar Mill Roll Selection Between China and Abroad

In recent years, a significant gap has existed in roll selection between Chinese and foreign mills. For example, Sweden’s Sandvik CIC tungsten carbide roll rings were promoted in China in the 1990s, but after over a decade, fewer than five mills use them. Although more mills are trying imported carbide rings, few repeat purchases due to high cost and demanding conditions—effectiveness depends on usage and maintenance, which is a conceptual barrier for many. Two years ago, UK’s British Steel and Germany’s Barton used high-speed steel in finishing stands.

Recently, Synnex leaders inspecting Japanese mills found a major shift: pearlitic nodular iron for roughing, semi-high-speed steel for intermediate, and high-speed steel for finishing. Rolls supplied to the US by Synnex are still pearlitic and bainitic nodular iron, but they expect a full shift to Japanese-style selection in 3–5 years. China will likely take longer to adopt these changes.

Birth and Development of Centrifugal Composite Rolls

Rolls have existed since the invention of rolling mills. Early rolls were sand-cast, later metal-mold cast. Tangential gating from the mold bottom was a leap forward. As rolling technology advanced, demands grew for rolls with high hardness, wear resistance, impact resistance, thermal crack resistance, and no slipping, while cores needed high strength and minimal deformation. These conflicting needs led to composite rolls via semi-flushing or full-flushing.

Semi-flushing involves pouring alloy iron from the mold bottom, stopping at the upper neck-body junction, allowing a shell to form, then adding ferrosilicon-stirred iron to strengthen the core.

Full-flushing pours alloy iron to the junction, pauses for shell formation, then replaces with high-strength core iron via the bottom gate, displacing original core iron from the riser. This was another leap in roll technology.

In 1968, Japan’s Kubota announced the successful development of centrifugal composite cast iron rolls, perfecting composite roll manufacturing. Over 35 years, centrifugal composite technology advanced rapidly, evolving through eight generations:

First Generation: Chilled or indefinite chilled composite rolls—outer layer of chilled or indefinite chilled iron, core of gray iron. Key technologies: centrifugal process, mold slag development, and cold coating.

Second Generation: Spherical core composite rolls—outer layer of chilled or indefinite chilled iron, core of nodular iron. Key issue: mitigating bonding layer black lines affecting spalling resistance.

Third Generation: Nodular composite cast iron rolls—outer and core layers of alloy nodular iron. Key challenge: preventing nodular degeneration and remelting.

Fourth Generation: High-chromium composite cast iron rolls—outer layer of high-chromium iron, core of nodular iron. Key issue: reducing core damage from chromium expansion, sometimes requiring triple-layer composites.

Fifth Generation: High-chromium composite cast steel rolls—outer layer of high-chromium steel, core of nodular iron or graphite steel. Key challenges: reducing chromium diffusion and determining centrifugal parameters.

Sixth Generation: Composite cast steel or semi-steel rolls—outer layer of alloy steel or semi-steel, core of ordinary cast steel or graphite steel. Key technologies: centrifugal process parameters and high-melting-point mold powder.