Selection of Materials for Rolling Mill Rolls

Work Roll Material Selection

Roughing Mill Work Rolls (Before R1):

Roughing work rolls must be tough, wear-resistant, and resistant to thermal cracking. The typical hardness range is HS 40-55. Rolls made from materials such as 60CrNiMo cast steel are commonly used.

Roughing Mill Work Rolls (After R2):

Post-roughing work rolls require high crack resistance. Materials typically selected include semi-steel, high-chromium steel, and high-speed steel.

Finishing Mill Work Rolls (Stands F1-F4):

Work rolls in the front section of the finishing mill operate under high temperatures and heavy loads. Commonly used materials are cast semi-steel and high-chromium centrifugal composite cast iron. The latter offers superior roll surface wear resistance, thermal crack resistance, and helps suppress surface defects.

Finishing Mill Work Rolls (Stands F5-F7):

Work rolls in the final finishing stands critically influence final product quality and surface finish. These rolls require high hardness, excellent wear resistance, indentation resistance, spalling resistance, and thermal crack resistance. Materials typically chosen are indefinite chilled cast iron (standard or improved grades).

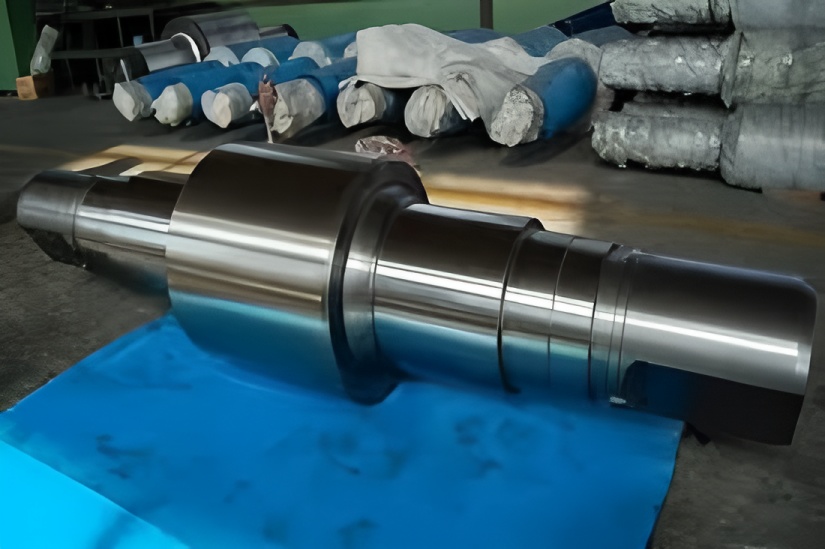

Selection of Backup and Vertical Roll Materials

Backup rolls for both roughing and finishing mills require good thermal crack resistance, wear resistance, fatigue strength, and high overall strength. Materials generally used include composite cast steel and alloy forged steel (e.g., Cr3, Cr5 grades).