Solving Oxide Film Peeling on Rolling Mill Rolls

Description: Peeling of the oxide film on rolling mill rolls significantly impacts strip surface quality. Effective control of this issue requires a systematic and comprehensive approach.

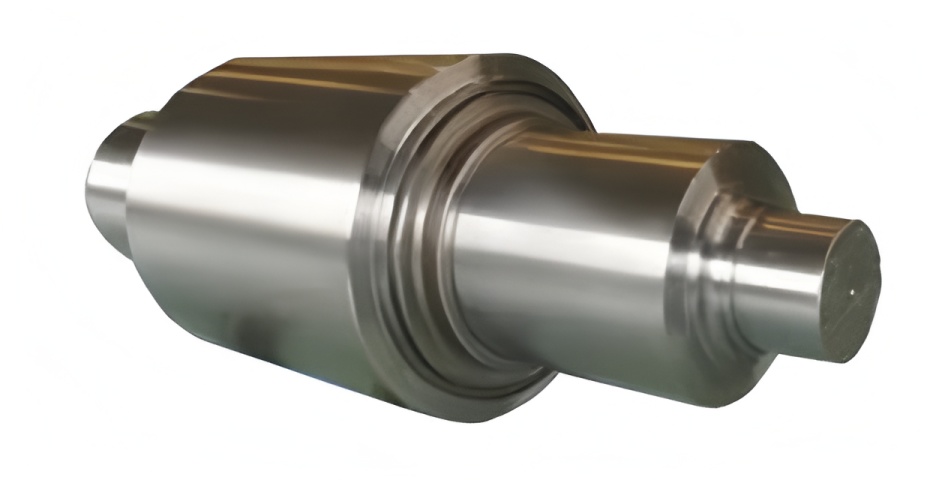

Keywords: Rolling mill rolls

In a 1780 mm hot tandem rolling mill, peeling of the oxide film on the finishing mill work rolls severely compromised strip surface quality, resulting in approximately 1,500 tons of steel coils being scrapped monthly.

The causes of oxide film peeling were analyzed from multiple aspects, including roll material, roll cooling water, descaling water, rolling lubrication, and water scraper plates. Through optimization of roll cooling water, adjustment of descaling water spray position, elimination of header interference, and improvement of water scraper configuration, the issue was effectively resolved. This resulted in a over 90% reduction in scrap and defective products caused by oxide film peeling, leading to significant waste reduction and cost savings for the company.

Root Cause Analysis of Oxide Film Peeling on Rolls

During hot rolling, an oxide film forms on the roll surface under high temperatures, protecting the roll. The quality of this oxide film critically affects roll service life, making control of its thickness essential. If the oxide film is too thin, it fails to protect the roll, leading to crushing during rolling and resulting in a rough roll surface. Additionally, fine particles from the shattered oxide film can be pressed into the strip surface, causing defects such as pinholes. If the oxide film is too thick, it tends to spall off in large pieces, severely affecting strip surface quality.

The peeling of the oxide film is mainly influenced by the following factors:

(1) Roll Material

Common roll materials in industrial production include indefinite chilled iron, high-chromium cast iron, and high-speed steel. In the 1780 mm hot rolling mill, the work roll material for stands F1–F4 was changed from high-chromium cast iron to high-speed steel.

High-speed steel rolls have a higher friction coefficient than high-chromium cast iron rolls, resulting in 10–20% greater rolling force. Increased rolling force raises the heat transfer coefficient between the strip and the roll, leading to more heat transferred to the roll. Additionally, high-speed steel has a larger thermal expansion coefficient and poorer heat dissipation, causing the average roll temperature to be significantly higher than that of high-chromium cast iron rolls. Therefore, high-speed steel rolls require better cooling conditions. Ideally, the surface temperature of high-speed steel rolls should be kept below 60°C. However, the temperature of F1–F4 work rolls in the 1780 mm hot rolling mill exceeded 70°C, primarily due to insufficient cooling efficiency of the roll cooling water.

(2) Roll Cooling Water

During hot rolling, the roll contacts the high-temperature strip, causing its temperature to rise rapidly. Roll cooling water removes heat, maintains a lower roll temperature, controls thermal expansion and crown, and reduces roll wear. Additionally, cooling water lubricates the roll, reduces the friction coefficient, and decreases rolling force.

The pressure and flow rate of the cooling water are critical to its effectiveness. Excessively high pressure causes water to splash off the roll surface, reducing cooling efficiency. The water volume mainly affects the formation of the oxide film. Too much water makes it difficult to form an oxide film, increasing roll wear and affecting strip surface quality. Too little water allows the oxide film to grow too thick and spall off, forming visible peeling bands. Therefore, a cooling system with lower pressure and higher flow rate is recommended to ensure adequate heat removal and higher cooling efficiency.

For high-chromium cast iron work rolls, the recommended water pressure is 0.5–1.0 MPa. The minimum cooling water flow for the 1780 mm finishing mill’s high-chromium cast iron rolls is calculated to be 660 m³/h. Based on practical experience, the actual flow should be 20% higher than the theoretical value. For high-chromium cast iron rolls, the minimum cooling water requirement is 4.5 m³/(cm·h), making the minimum flow for the 1780 mm finishing mill 801 m³/h. With the 20% increase, the required flow for F1–F4 work rolls becomes 961.2 m³/h.

The 1780 mm hot rolling mill’s finishing stands F1–F4 use roll cooling water at a pressure of 1.0 MPa and a flow between 1,000 and 1,250 m³/h, meeting the theoretical requirement. Comparative analysis with similar hot rolling lines confirmed that the existing cooling water was sufficient, indicating that the peeling issue was not due to insufficient water volume but rather the inefficiency of cooling for high-speed steel rolls. The high measured roll temperatures confirmed that cooling efficiency required further investigation.

Heat accumulation on the work roll is concentrated slightly above the exit side, making cooling efficiency in this area crucial. The work roll cooling system has two pipes on the entry and exit sides. The exit side cooling water remains in contact with the roll longer and has higher efficiency. Therefore, the distribution of cooling water significantly affects cooling performance, and the exit flow should be much larger than the entry flow. The original design allocated 70% to the exit and 30% to the entry, resulting in low efficiency. Increasing the exit flow ratio helps reduce roll temperature and prevents excessive oxide film growth and peeling.

Additionally, the poor quality of the cooling water for the 1780 mm finishing mill work rolls easily clogged the nozzles, causing local oxide film overgrowth and peeling.

(3) Descaling Water

Descaling water helps prevent oxide film peeling and scale intrusion. It reduces strip surface temperature, minimizes the temperature difference when the strip contacts the roll, reduces thermal cracks causing spalling, and improves the roll surface condition. The original design positioned the descaling water spray too far from the bite point, allowing the strip surface to turn red upon entry and reducing its effectiveness in minimizing the temperature difference. Moreover, descaling water was obstructed by the upper guide plate, further reducing cooling efficiency.

(4) Rolling Lubrication

Rolling lubricant forms a protective film on the roll surface, reducing the friction coefficient, rolling force, and roll temperature. It decreases online roll wear, prevents work roll sticking, and extends roll service life. Lubrication also improves roll surface condition, prevents scale pressing, and enhances strip surface quality. The 1780 mm hot rolling mill’s finishing unit was equipped with rolling lubrication, but interference between headers and other functional components in the mill hindered its effectiveness.

(5) Water Scraper Plates

The upper work rolls of the finishing mill are equipped with water scraper plates. The original design included reinforcing ribs in the guide frame for strength but omitted drainage holes, causing water accumulation during rolling. The counterweight of the upper water scraper plate was insufficient, leading to incomplete water scraping, which hindered the formation of a lubricating oil film on the roll surface and affected rolling lubrication. Additionally, no water scraper plate was installed between the descaling water and rolling lubricant for the lower work roll at the entry, causing mutual interference. Descaling water falling onto the lower work roll surface prevented lubricant from covering the high-speed steel rolls, impairing lubrication effectiveness. Furthermore, the original cast iron water scraper plates easily scratched the stable oxide film on the roll surface, causing peeling.

Technical Improvement Implementation

(1) Confirmed that the original roll cooling water was sufficient and no changes to the supply system were needed. To improve cooling, the inlet/outlet cooling water ratio for work rolls was adjusted from 30%/70% to 15%/85%.

(2) Optimized filtration devices and nozzle selection on pipelines, improved cooling water quality for work rolls, and prevented nozzle clogging.

(3) Adjusted the spray position of descaling water closer to the bite point.

(4) Increased the counterweight of water scraper plates, added drainage holes to rib plates, and changed the material of water scraper plates to enhance water retention and drainage.

(5) Added a water scraper plate between the descaling water and rolling lubricant for the work roll at the entry to eliminate interference, allowing lubricant to evenly cover the roll surface and improve lubrication effectiveness.

(6) Adjusted the relative positions and spray angles of headers in the mill to resolve mutual interference.

Transformation Results

(1) Optimized roll cooling water improved cooling efficiency, reduced roll temperature from above 70°C to below 60°C, and extended the service life of high-speed steel rolls.

(2) Shortened the time between descaling water spray and strip entry, reduced the temperature difference when the strip contacts the rolls, and enhanced descaling water effectiveness.

(3) Eliminated interference among headers for descaling water, lubricant, cooling water, and scale breaking water, ensuring normal functionality.

(4) Greatly improved roll surface quality and reduced oxide film peeling on work rolls.

(5) Reduced consumption of high-speed steel rolls by 15%.

(6) Effectively resolved strip quality issues caused by oxide film peeling. Monthly scrap and defective products decreased from 1,500 tons to less than 100 tons, a reduction of over 90%. The increased revenue reached over 40 million yuan, delivering remarkable economic benefits.