Keywords: Steel Plate Production, Rolls

Description:

Surface defects in medium and heavy steel plates are categorized into inherent steel defects (related to the material itself) and operational defects (caused during production). How can these defects be prevented?

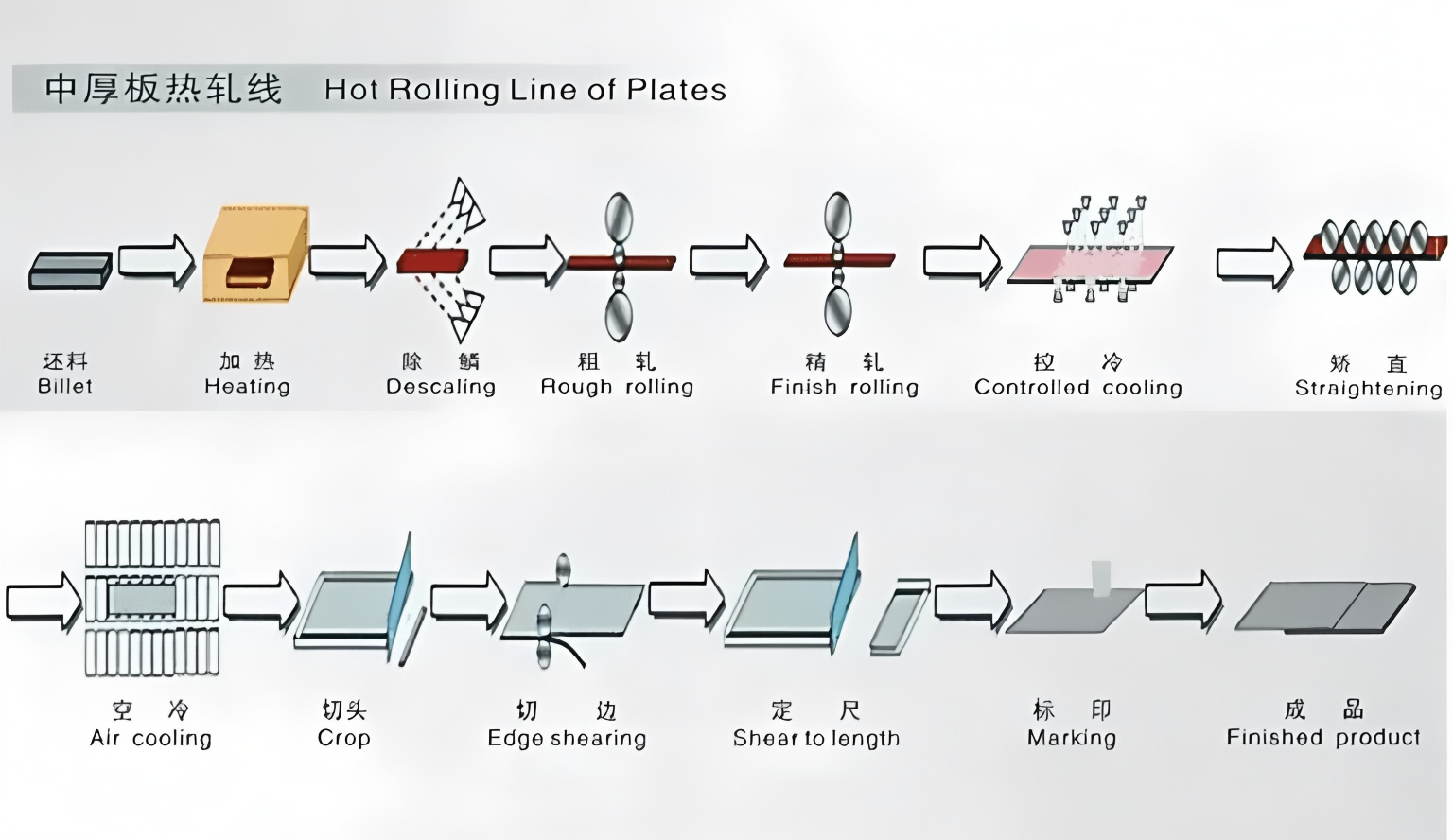

Steel Plate Production Process

Common Defects in Medium and Heavy Steel Plates

Surface defects in such plates are classified into two types based on origin:

Steel defects: Originating from the billet itself.

Operational defects: Arising during production from billet to finished plate.

Steel Defects

Cracks and Fissures

Characteristics:

Cracks vary in shape, depth, and length—often resembling fish scales or water ripples. They may occur individually anywhere or densely along plate edges.

Causes:

Incomplete removal of cracks from continuous casting billets; original surface cracks (longitudinal, transverse, or star-shaped) become exposed after rolling.

Subsurface bubbles or inclusions break open during rolling, forming point or star-shaped cracks.

Non-uniform heating leading to uneven plasticity and cracking during rolling.

Inadequate soaking time or temperature non-uniformity in low-thermal-conductivity steels, causing excessive internal stress and cracking during rolling or cooling.

Prevention:

Enhance billet quality inspection; thoroughly clean surface cracks.

Avoid billet overheating; control heating speed for temperature uniformity.

Use high reductions during hot rolling to heal subsurface bubbles.

Bubbles

Characteristics:

Irregularly distributed circular bulges with smooth edges, caused by internal gas that fails to weld during rolling; some may tear open.

Causes:

Accumulated gas inside the billet.

Prevention:

Improve steelmaking practices to remove gas.

Strictly inspect billets; reject those with visible bubbles.

Surface Inclusions

Characteristics:

Visible non-metallic inclusions (reddish-brown, light yellow, or off-white) appearing as spots, blocks, or streaks; severe cases may evolve into cracks.

Causes:

Inherent inclusions in billets exposed after rolling; mold slag entrapment or nozzle damage during continuous casting.

Refractory materials (e.g., furnace lining) falling onto billets during heating and being pressed into the surface.

Prevention:

Strengthen billet cleaning and inspection; reject billets with inclusions.

Maintain high-pressure water descaling to remove scale and debris.

Operational Defects

Convex Hulls and Indentations

Characteristics:

Convex hulls: regular local protrusions; indentations: pits of various shapes/sizes.

Causes:

Convex hulls: roll surface damage or pits caused by hard objects.

Indentations: hard objects (e.g., slag, iron chips) adhering to rolls during rolling or straightening.

Foreign objects falling onto the plate during straightening, pressed in and later dislodged.

Prevention:

Avoid rolling improperly heated billets; ensure uniform roll cooling.

Regularly inspect rolls; replace if damaged or contaminated.

Prevent foreign objects from contacting the plate during processing.

Pitting

Characteristics:

Local or continuous pits, categorized by cause:

Black spots:蜂窝状 rough pits from fuel spray erosion during heating.

Light pitting: smooth, off-white pits from severe oxidation and scale loss.

Heat treatment pits: regular/large-area pits from adhesion to furnace rollers during normalization.

Causes:

Fuel impingement during heating.

Heavy oxidation during heating.

Adhesion of high-melting-point combustion products to furnace rollers during heat treatment.

Prevention:

Control furnace temperature fluctuations, fuel injection, and atmosphere.

Enhance descaling; ensure high-pressure water effectiveness.

Regularly clean heat treatment furnace rollers to reduce buildup.

Oxide Scale Pressing

Characteristics:

Taupe or reddish-brown scale pressed into the plate in patches or streaks.

Causes:

Incomplete removal of primary or secondary scale during rolling.

Poor adhesion of secondary oxide scale formed during rough rolling or cooling, not fully removed by high-pressure water.

Prevention:

Optimize heating temperature, atmosphere, and duration to minimize oxidation.

Maintain high-pressure descaling, especially before finishing mills.

Overburning

Characteristics:

Slight cases: diamond, chicken-foot, or serpentine cracks at edges/corners; severe cases: coarse fibrous structure with oxidized grain boundaries under microscopy.

Causes:

Excessive heating temperature or prolonged high-temperature soaking.

Direct flame impingement on billet surface.

3.Localized overheating due to uneven furnace temperature.

4.High manganese or sulfur content increasing susceptibility.

Prevention:

Set appropriate heating parameters based on steel grade and furnace conditions.

Control furnace atmosphere and flame length; avoid direct flame contact.

Reduce temperature as needed during prolonged rolling delays.