Description: Four TC4 titanium alloy rolled plates of different thicknesses were selected for study. Their microstructure and mechanical properties were investigated using metallographic microscopy and mechanical testing.

Keywords: TC4 titanium alloy plate; metallographic structure; mechanical properties; anisotropy; fracture morphology

Abstract: The microstructure of TC4 titanium alloy sheet after rolling and annealing consists of a mixed structure of α phase and residual β phase. The α phase exhibits characteristics of elongated strips, equiaxed grains, and fine clusters. The overall strength of the TC4 titanium alloy plate shows a trend of initial decrease followed by stabilization as thickness increases, while plasticity initially increases and then stabilizes. At a thickness of 0.8mm, the TC4 titanium alloy sheet demonstrates a tensile strength of 1075 MPa and yield strength of 1027 MPa. The strength and plasticity of the rolled and annealed TC4 plate differ along the rolling direction (RD) and transverse direction (TD). The fracture morphology of TC4 plates across different specifications is primarily ductile. Additionally, the 0.8mm thick TC4 plate exhibits a certain number of small cleavage facets and numerous fine microcracks within the dimples.

TC4 titanium alloy (nominal composition Ti-6Al-4V) is a typical α+β dual-phase alloy renowned for its excellent corrosion resistance, high toughness, good high-temperature mechanical properties, and other superior characteristics. It is widely used in aerospace engines, marine engineering, chemical engineering, and other fields, and is often referred to as an all-purpose titanium alloy.

The production process of TC4 titanium alloy primarily includes smelting, forging, and rolling. Currently, the application of rolled TC4 titanium alloy plate is extensive [3-4]. Han Ying et al. studied the influence of rolling process on the texture evolution and properties of TC4 sheet, showing that forward rolling refines grains and elongates α grains; cross rolling results in more uniform grain breakage and generates numerous equiaxed α grains; both processes provide good plasticity but lower strength. Wang Wei et al. [6] studied the effect of rolling passes on the microstructure, texture, and mechanical properties of electron-beam melted TC4 alloy, finding that increased passes break down the original coarse as-cast structure, align the grains axially, promote formation of fine α phase, and increase low-angle grain boundaries by 35.1% after three passes. This paper analyzes TC4 plates produced under different rolling specifications, exploring the relationship between microstructure and mechanical properties for different thicknesses, providing a reference for actual production.

1. Test Materials and Methods

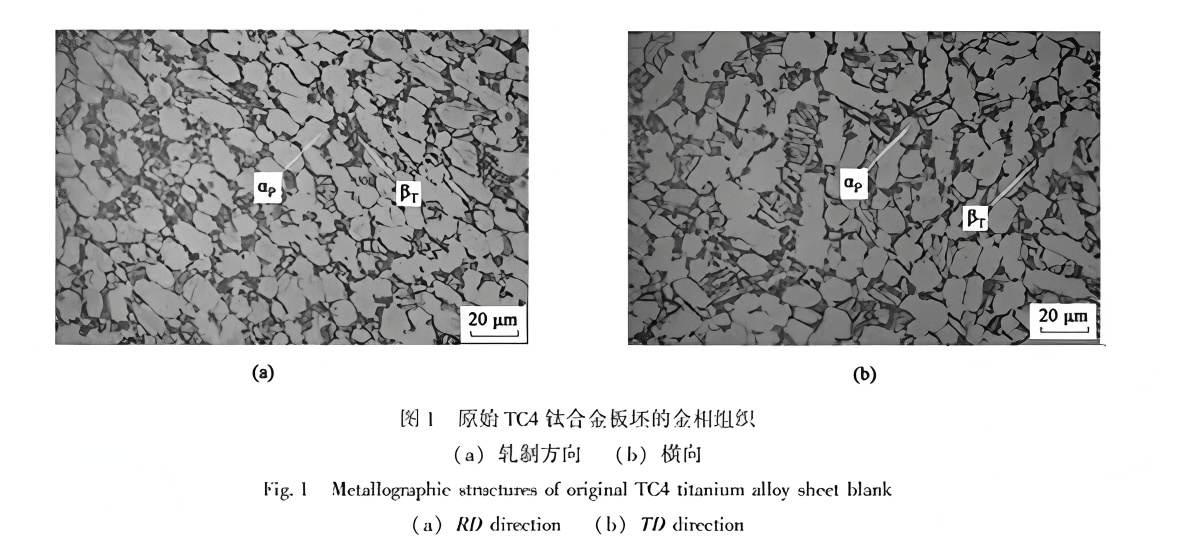

The TC4 titanium alloy slab used in this test measured 250 mm × 1000 mm × 2000 mm. After heating in a tunnel natural gas furnace and a bottom-resistance furnace to temperatures between 850–1020°C, it was processed on a φ900/φ840 mm × 2450 mm four-high reversible hot rolling mill. The first three passes were rough rolling, reducing thickness to 50.0 mm, 6.0 mm, and 3.5 mm respectively. The fourth pass was finish rolling, reducing the 3.5 mm semi-finished plate to final thicknesses of 2.0, 1.5, 1.0, and 0.8 mm. The plates were then annealed at 780°C for 2 hours. Their specific compositions are shown in Table 1. The original metallographic structure of the slab is shown in Figure 1, exhibiting an equiaxed structure in both longitudinal and transverse directions, dominated by large primary α phase (αp) and β-transformed structure (βt) consisting of secondary α phase lamellae and secondary α phase on the β matrix.

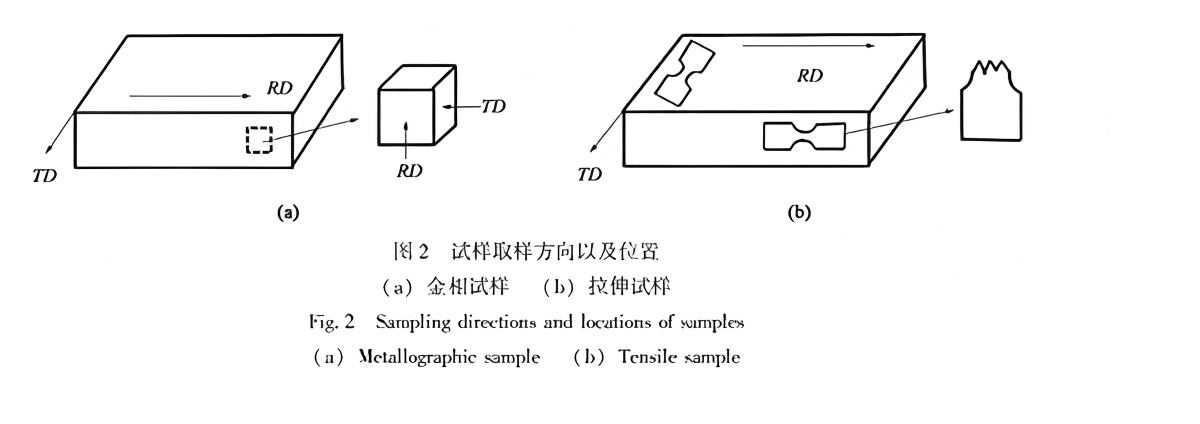

The phase transformation point of the TC4 plate, tested according to GB/T 23605-2009, was determined to be 995–1000°C. Samples from the four plate specifications were sectioned and processed for metallographic examination and room-temperature tensile testing. Figure 2 shows the sampling directions: rolling direction (RD) and transverse direction (TD). Figure 2a indicates the metallography sampling location, and Figure 2b shows the tensile sample location and fracture observation area. Microstructure was observed using an OLYMPUS optical microscope. Room-temperature and high-temperature tensile tests used an INSTRON-5580 universal testing machine. Grain size was measured using Image Pro5 software. Fracture morphology was examined using a Quanta scanning electron microscope. Three samples were tested for each condition, and average values were taken.

2. Results and Discussion

2.1 Metallographic Structure

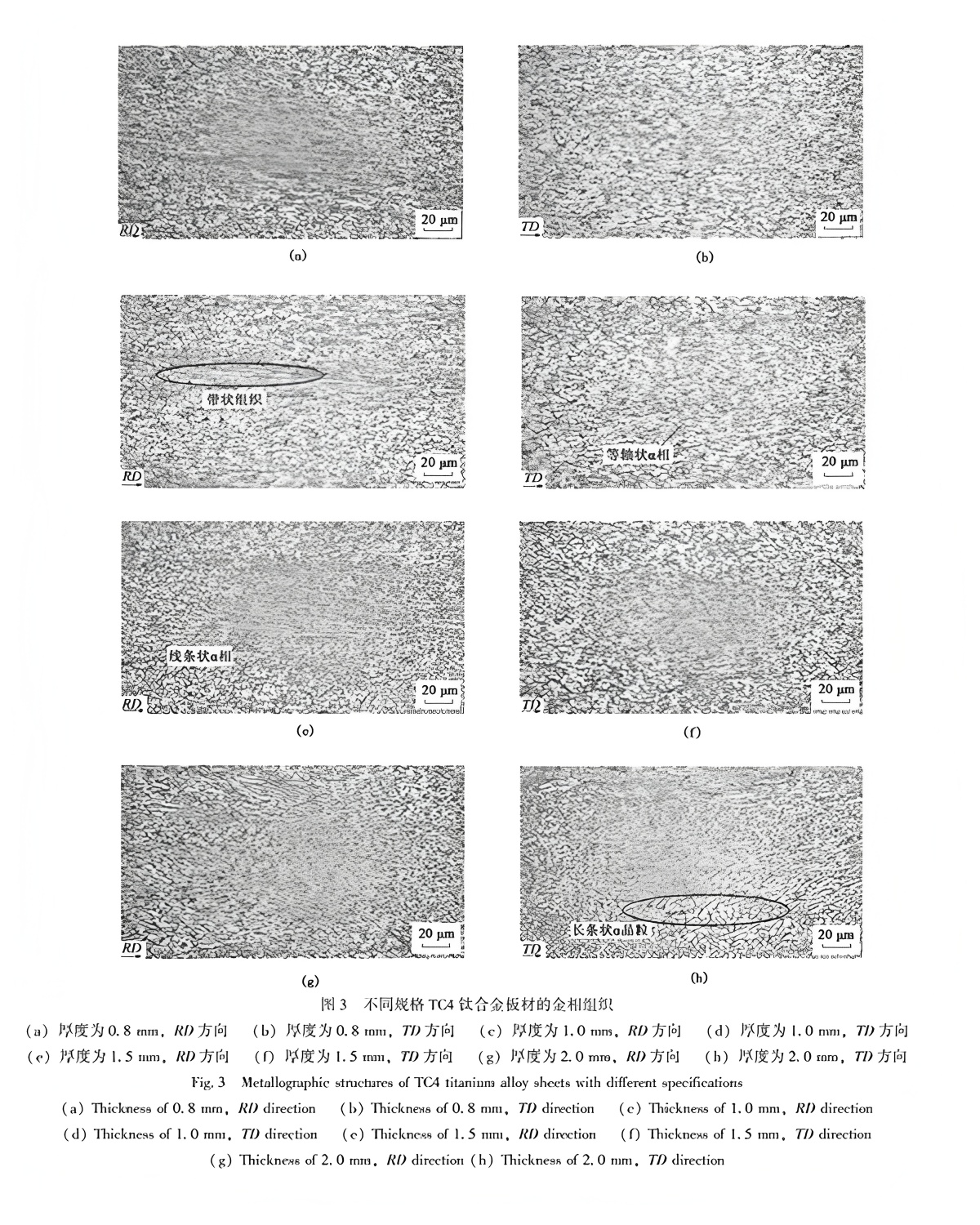

Figure 3 shows the metallographic structure of TC4 plates of different specifications. After rolling and annealing, the microstructure consists of a mixture of α phase and residual β phase. The α phase morphology varies with thickness, showing elongated, equiaxed, and fine clustered shapes, with residual β phase distributed between α phases. Compared to the original slab, the rolled and annealed TC4 plates show significant grain refinement and clear rolling deformation marks, indicating complete dynamic recrystallization. In the RD direction of the 0.8mm, 1.0mm, and 1.5mm plates, banded structure is most apparent in the 1.0mm plate. This is because during rolling, grain alignment and orientation on the prism and basal planes do not change significantly (only a tendency for the c-axis to shift from TD towards ND, creating a strong basal texture), but pyramidal slip can cause grain tilting, leading to recrystallization or rotation. The banded structure is less obvious in the 2.0mm plate, where α grains are elongated, unevenly distributed, and appear as long strips. All four microstructures primarily consist of fine equiaxed α grains, with no obvious banding observed.

Both RD and TD directions contain numerous fine α grains, indicating altered stress states during rolling. The original slab grains were not twisted in a fixed direction; stored strain and high dislocation density in the deformation zone provided strong driving energy for recrystallization nuclei, facilitating recrystallization during annealing and producing many fine equiaxed α grains [8]. This aligns with findings by Wang Niujun et al. [9] on TC4 plate under different processing conditions, confirming the grain-refining effect of rolling.

2.2 Tensile Properties

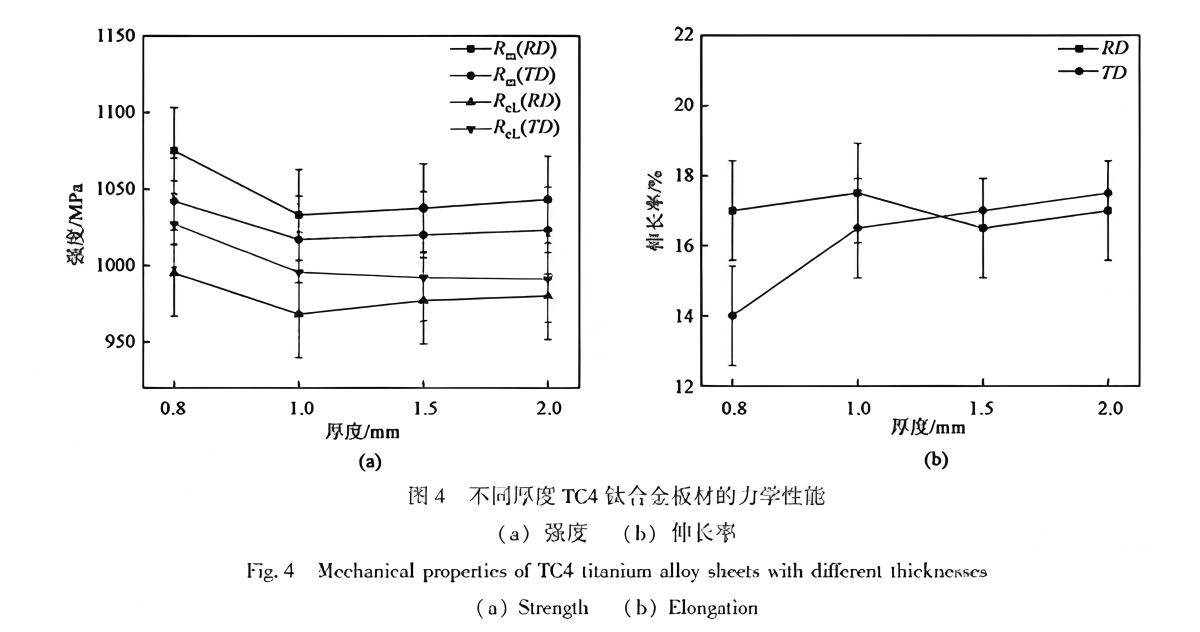

Figure 4 shows the mechanical properties of TC4 plates of different thicknesses, and Figure 5 shows the engineering stress-strain curves. Strength generally decreases initially and then stabilizes with increasing thickness, while plasticity increases first and then stabilizes. Annealing reduces work hardening and dislocation density from rolling, releasing internal stresses. The 0.8mm plate exhibits the highest strength: tensile strength Rm = 1075 MPa, yield strength Rp0.2 = 1027 MPa. Elongation (A) is roughly similar across plates, with a maximum of 17.5%.

During room-temperature tensile testing, dislocations accumulate at α/β interfaces under stress. Under the combined action of dislocation force and crack tip stress, α/β layers separate, microcracks expand through void coalescence, eventually leading to fracture [10]. The higher strength of the 0.8mm plate is attributed to greater rolling deformation, higher matrix distortion, more stored energy providing more recrystallization nucleation sites, and finer grains offering stronger obstacles to dislocation motion. Dislocation pile-ups form in fine-grained regions, requiring higher stress to reactivate slip, thus increasing strength.

Figure 4 shows differences in properties along RD and TD, most pronounced in the 0.8mm plate: a maximum difference of 33 MPa in Rm and 32 MPa in Rp0.2, while elongation differs by up to 3%, indicating some anisotropy. The RD direction generally shows higher tensile strength and good plasticity due to grain refinement increasing boundary area (grain boundaries are stronger than grains at room temperature), hindering dislocation slip and improving strength. Crack deflection during fracture increases the propagation path, enhancing elongation. Yield strength is lower in RD because tensile stress in RD forms a smaller angle with the {0001} basal plane, facilitating slip initiation and reducing yield strength. Subsequent work hardening and dislocation interactions during fracture lead to lower yield but high tensile strength. In TD, the larger angle between tensile stress and the {0001} plane makes slip systems harder to activate, requiring higher stress, thus increasing yield strength but making the structure more prone to stress concentration after yielding, reducing tensile strength.

2.3 Fracture Morphology

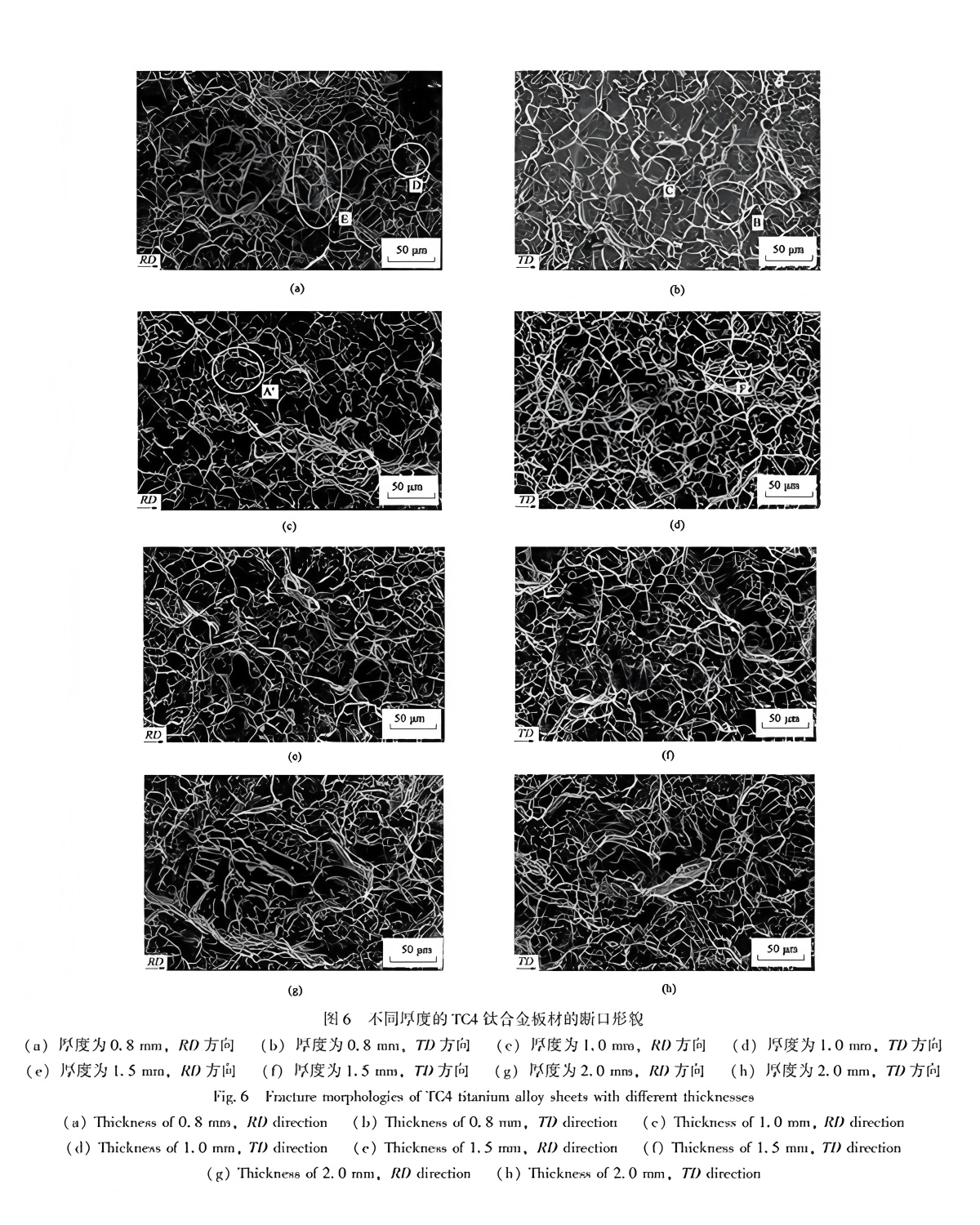

Figure 6 shows the fracture morphology of different TC4 plates after tensile testing. The morphology is generally similar, primarily ductile with equiaxed dimples (position A’). A few small dimples are distributed within larger ones, showing clear ductile fracture characteristics macroscopically corresponding to high elongation. Dimples form as equiaxed α phases act as void nucleation sites, followed by void growth and coalescence. Alloy plasticity is typically determined by dimple depth and size; deep, large dimples indicate good plasticity.

For the 0.8mm thick plate (Figs. 6a, 6b), both RD and TD directions show numerous dimples, some small cleavage facets (position B) with smooth, rounded bottoms and tiny voids, sharper edges, and many very fine microcracks within dimples (positions C, D). Under tensile stress, high stress concentration at crack tips causes secondary cracking perpendicular to the main crack during propagation, increasing crack tortuosity, thus increasing strength but reducing plasticity. Tear ridges (position E) in Fig. 6a also indicate higher strength and lower plasticity, consistent with macroscopic properties. For the 1.0mm thick plate (Fig. 6d, TD direction), voids (position F) appear because uniform fine grains cause stress concentration; encountering fine α grains during crack propagation leads to deflection and void formation along α/β boundaries, reducing plasticity. For 1.5mm and 2.0mm plates, fracture morphology is similar in RD and TD, indicating similar mechanical properties with small differences.

In the RD direction, thicker plates (1.5mm, 2.0mm) show fracture surfaces with numerous dimples. Thinner plate (0.8mm) exhibits tear ridges and microcracks due to higher deformation, increasing strength but reducing plasticity. The TD direction shows a similar trend: as thickness decreases, fracture morphology changes from solely ductile to a mix of dimples, microcracks, and voids. The difference is that for thin plate, RD fracture is primarily dimples, microcracks, and tear ridges, while TD is primarily dimples, microcracks, and voids.

Conclusion

(1) The microstructure of rolled and annealed TC4 titanium alloy plate consists of α phase and residual β phase. The α phase appears as elongated strips, equiaxed grains, and fine clusters. Compared to the original slab, grains are significantly refined with evident rolling deformation marks.

(2) With increasing thickness, the strength of TC4 plate initially decreases and then stabilizes, while plasticity initially increases and then stabilizes. The 0.8mm thick sheet has the highest strength: tensile strength Rm = 1075 MPa, yield strength Rp0.2 = 1027 MPa. Elongation (A) is similar across specifications, with a maximum of 17.5%. Differences in strength and plasticity between RD and TD directions indicate some anisotropy.

(3) The tensile fracture morphology of different TC4 plates is primarily ductile dimples, showing clear ductile fracture characteristics. The 0.8mm thick plate also shows some small cleavage facets in the TD direction, and numerous very fine microcracks within the dimples.