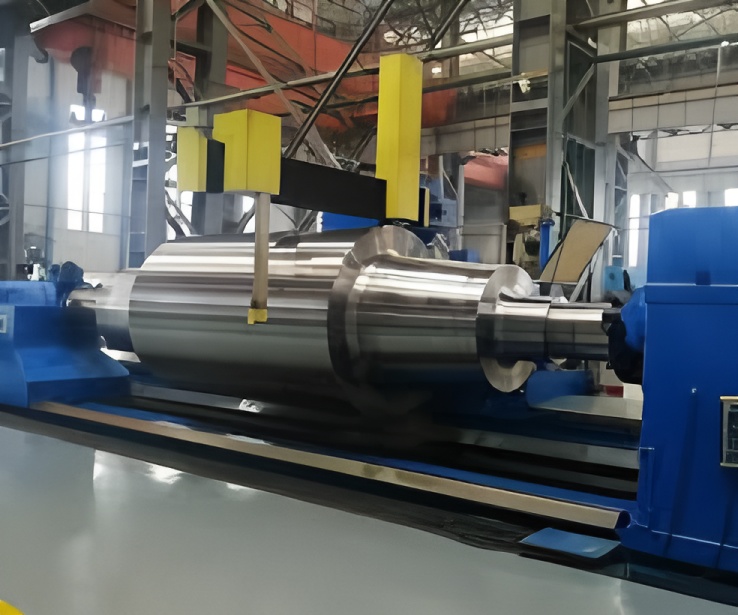

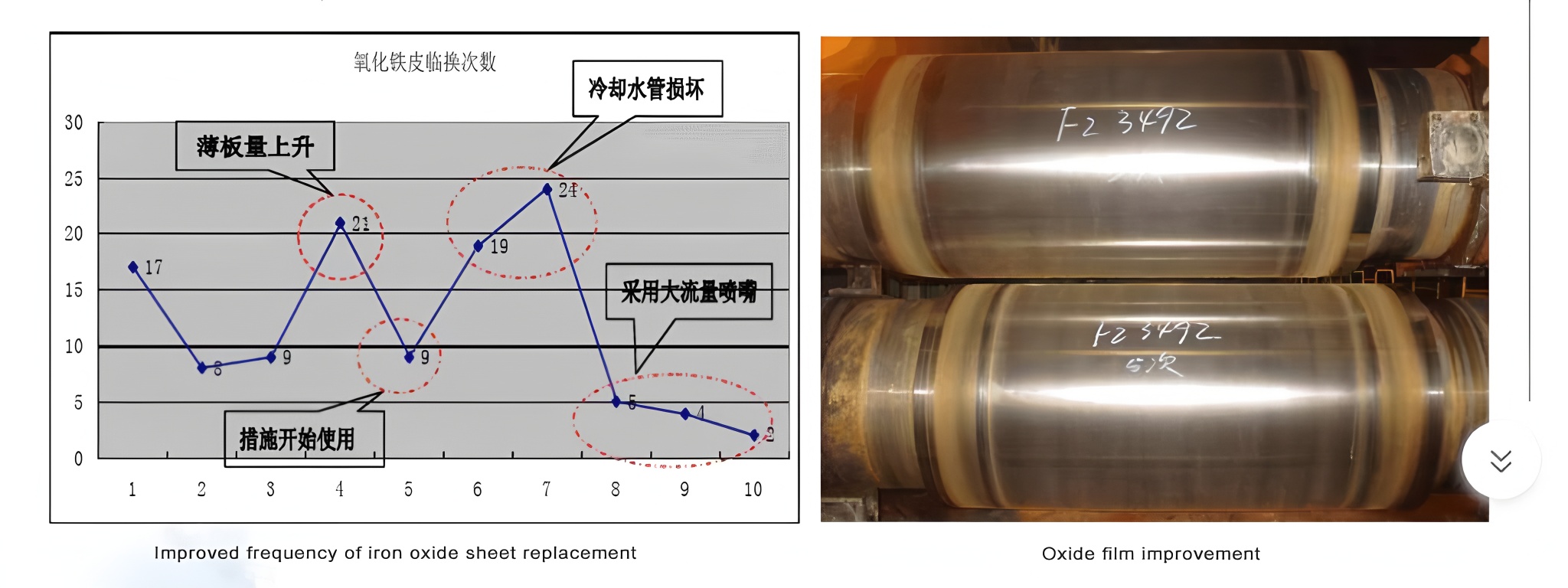

The operational integrity of high-speed steel (HSS) rolls in hot rolling mills is paramount for maintaining production efficiency and product quality. A common and disruptive issue is the spalling, or peeling, of the protective oxide film on the roll surface. This phenomenon not only leads to unscheduled and costly roll changes but also contributes to surface defects on the rolled steel and can cause blockages in production lines. In early 2021, a 1580 hot rolling mill experienced a significant increase in oxide film spalling incidents, averaging 14 emergency roll changes per month and peaking at 21, largely due to issues with the rolling oil system. This article provides an in-depth analysis, combining infrared thermal imaging and theoretical principles, to dissect the mechanism behind oxide film spalling on HSS rolls. Furthermore, it details a series of effective countermeasures, primarily focused on optimizing cooling strategies, that successfully mitigated this critical production problem.

Understanding HSS Roll Oxide Film: Formation and Spalling Mechanism

The oxide film on a hot rolling mill roll is not a defect; rather, it is a necessary protective layer that forms during operation. A stable, well-adhered film prevents direct metal-to-metal contact, reduces wear, and improves the surface finish of the rolled product. However, the characteristics of this film are highly dependent on temperature and mechanical stress.

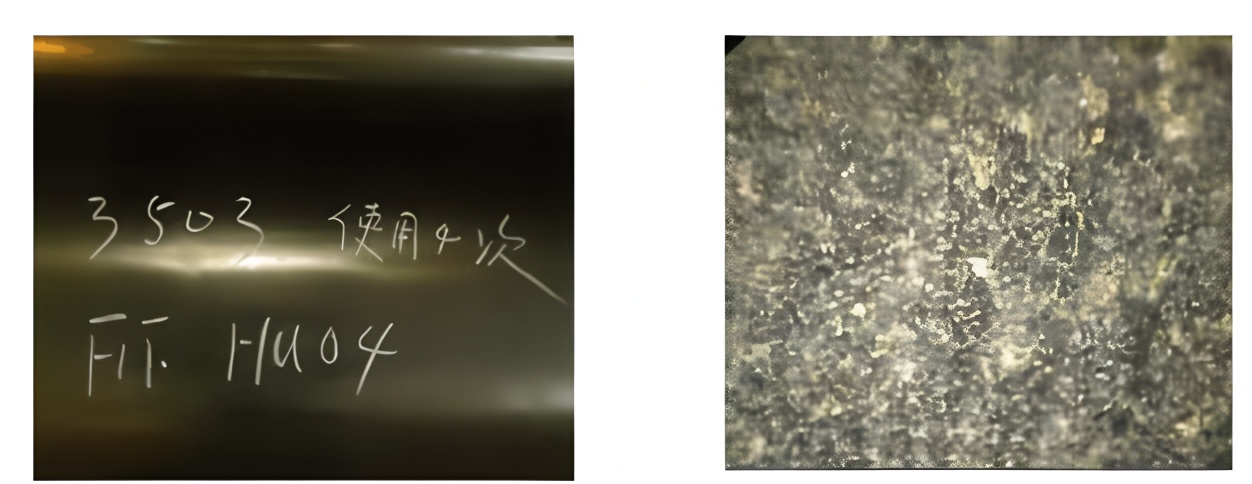

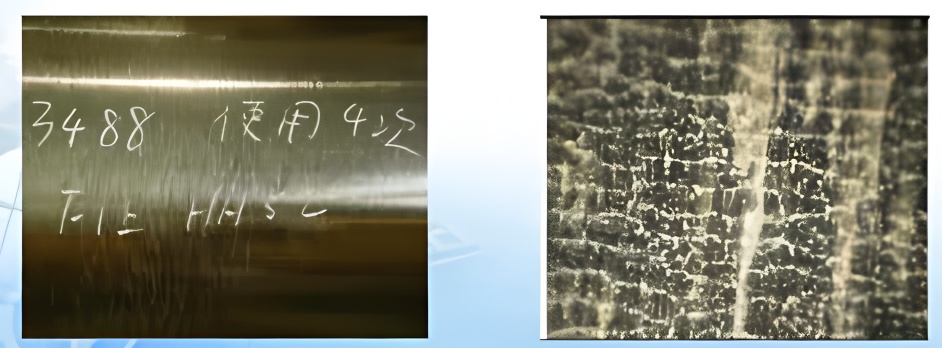

Oxide Film Morphology: Normal vs. Peeling

The visual appearance and microscopic structure of the oxide film are direct indicators of its health.

- ✓Normal (Healthy) Film: A desirable oxide film is thin, dense, and uniformly distributed across the roll surface. It typically presents a silver-gray or light-blue color, indicating a controlled thickness and strong adhesion to the roll substrate.

- ✗Peeling (Unstable) Film: When the film becomes excessively thick, its color darkens to a deep blue or black. This often signifies a thickness exceeding 3μm. At this stage, the film becomes brittle, and microscopic examination reveals significant cracking, which is the precursor to spalling.

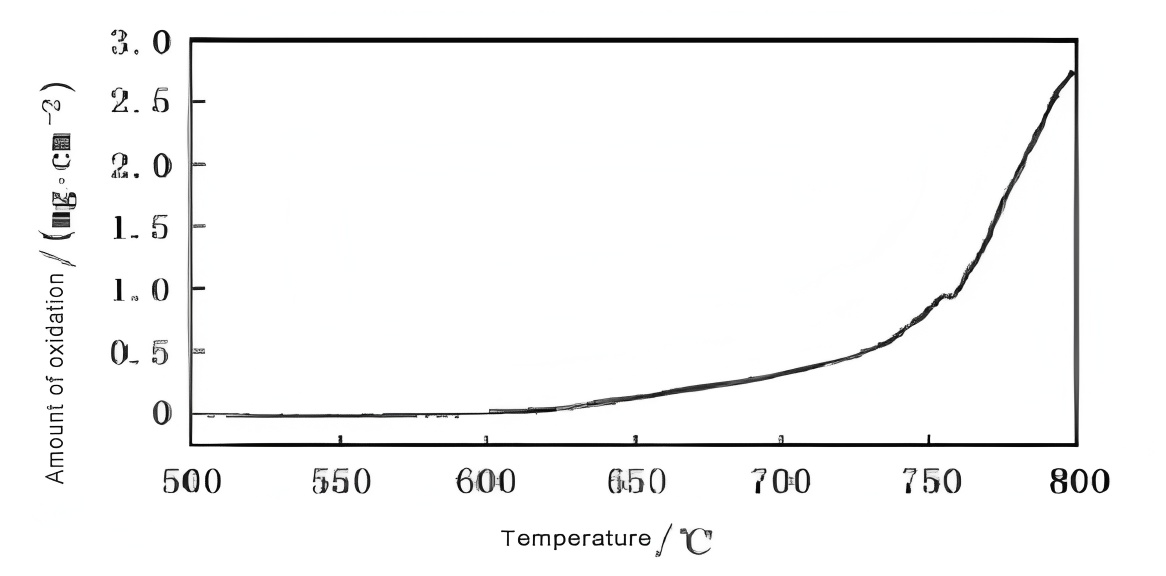

Oxide Film Growth Mechanism

The growth rate of the oxide film is exponentially related to the roll’s surface temperature. The process can be summarized in distinct temperature ranges:

- 500-600°C: In this range, the oxidation rate is very slow. The low thermal energy results in the formation of a thin, stable, and protective film.

- 600-700°C: As the temperature rises into this bracket, the oxidation process accelerates. The film begins to thicken at a more noticeable rate.

- Above 750°C: At these extreme temperatures, the oxidation rate becomes very rapid, leading to rapid and uncontrolled thickening of the oxide layer, making it brittle and unstable.

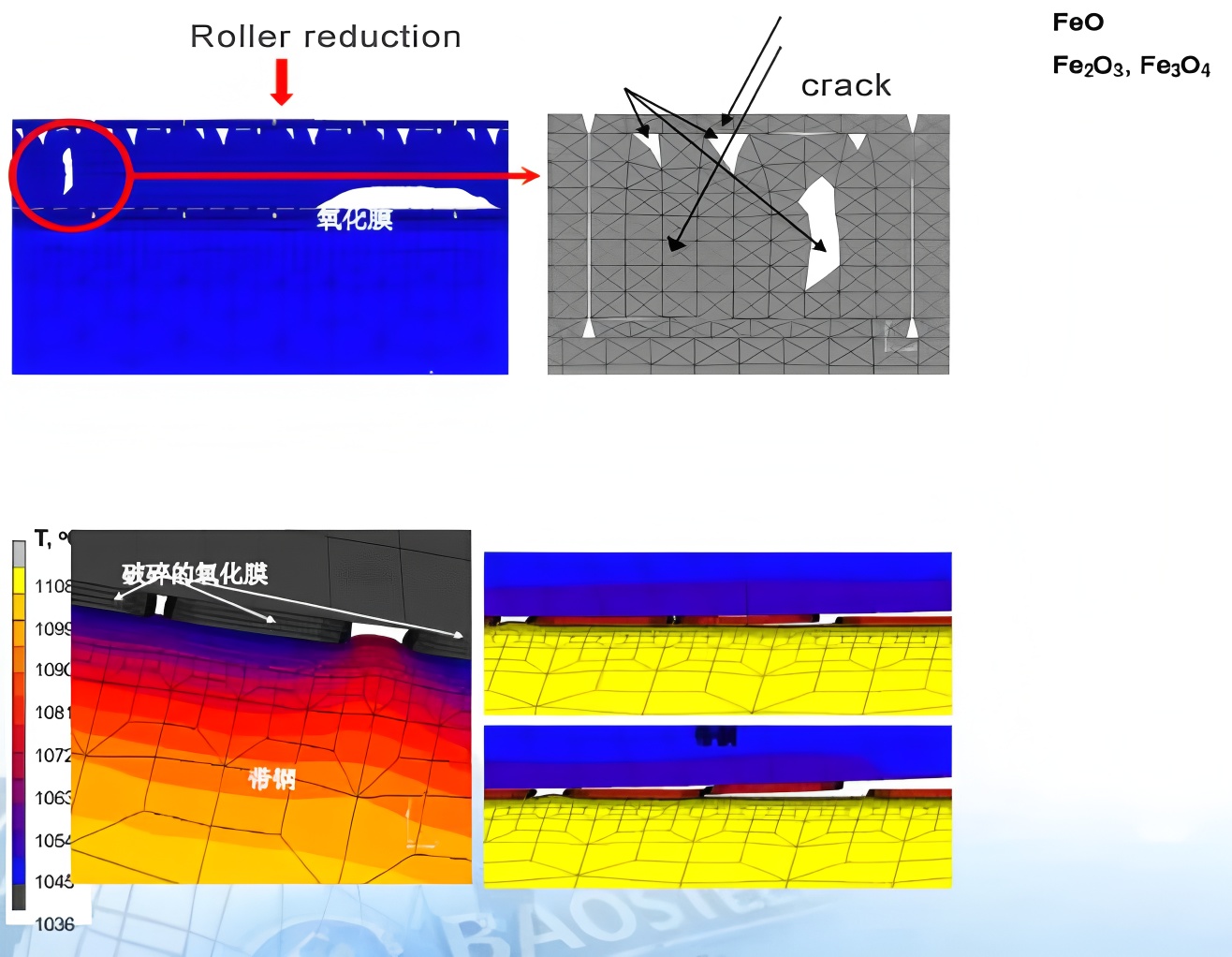

Oxide Film Spalling Mechanism

Spalling is not caused by a single factor but by the interplay of thermal and mechanical stresses. The process unfolds as follows:

- Crack Initiation: Under the immense and repeated application of rolling force, stress concentrates around hard carbide particles within the HSS roll’s microstructure. This initiates microcracks in the overlying oxide film.

- Film Thickening and Weakening: As the roll surface temperature spikes (especially above 600°C), the oxide film thickens rapidly. This thickened layer has lower shear strength and a weaker bond with the roll substrate compared to a thin film.

- Crack Propagation and Spalling: The combination of a brittle, thick film and continuous mechanical stress causes the initial microcracks to expand and connect. Eventually, large sections of the oxide film lose adhesion and flake off, an event known as spalling.

Field Test Study on Oxide Film Spalling

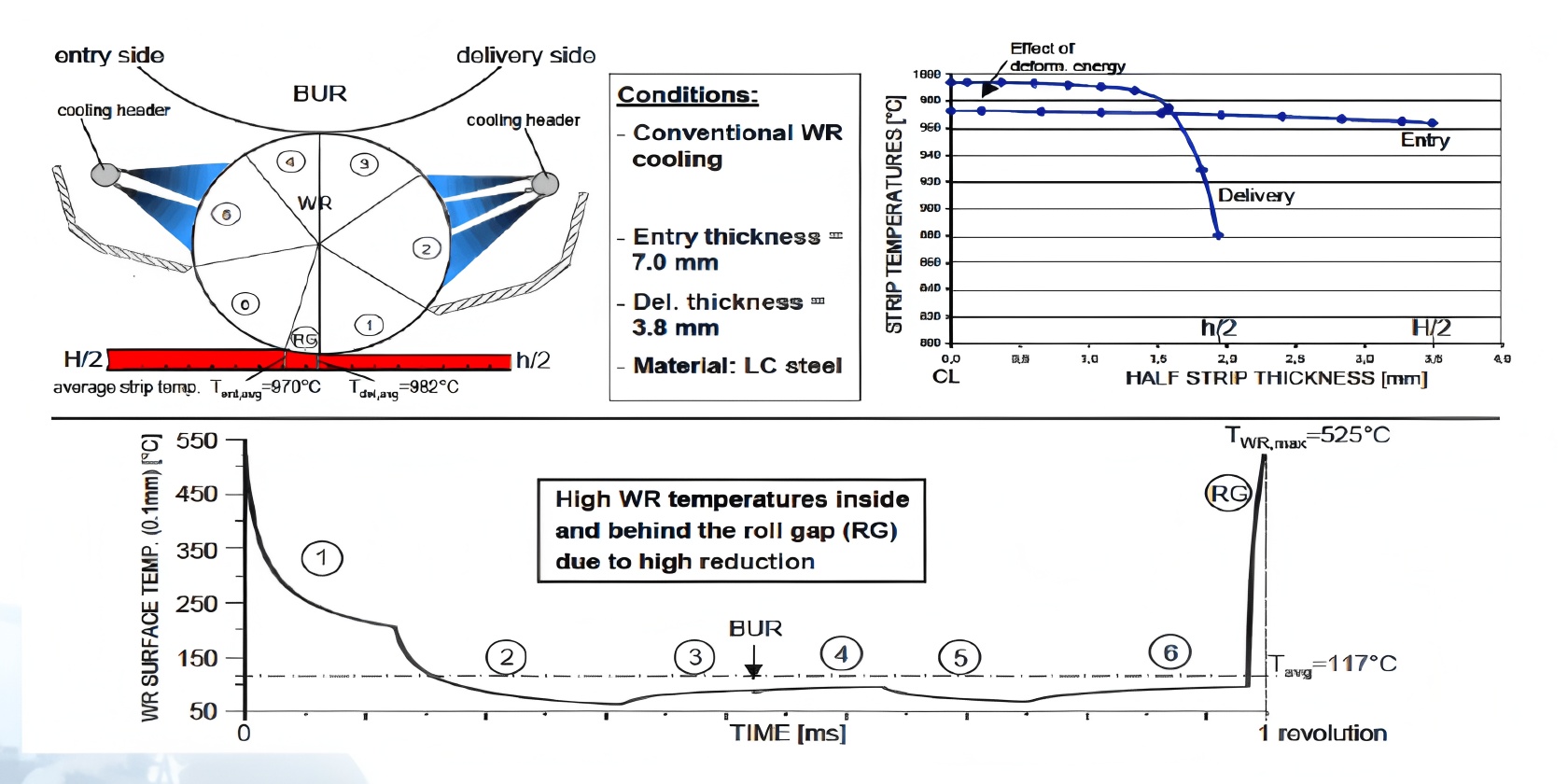

To validate the theoretical mechanism, a field study using infrared thermal cameras was conducted on the 1580 hot rolling mill. The study focused on measuring the transient surface temperatures of the rolls and the steel strip at various points in the finishing mill (stands F1-F4).

The research identified the “bite zone” (labeled RG area), the point of initial contact between the hot strip and the cooler roll, as the moment of maximum thermal shock. Here, the roll surface temperature experiences a dramatic and instantaneous spike. For a strip entering at 970°C, the roll surface can momentarily reach 525°C before being cooled by air and water sprays, with the average roll body temperature being much lower (around 117°C).

The tests revealed a critical temperature progression through the finishing stands:

- F1 Stand: After FSB descaling, the strip temperature dropped to ~1010°C. Upon biting, the F1 roll surface temperature would surge past 525°C, approaching the critical 600°C threshold where oxide growth accelerates.

- F2 & F3 Stands: Due to deformation heat, the strip temperature remained high (~1000°C) entering F2 and F3. This resulted in roll contact temperatures consistently exceeding 550°C, creating ideal conditions for rapid oxide film thickening and subsequent spalling.

- F4 Stand: After F3, the strip temperature finally dropped to ~900-950°C. Consequently, the F4 roll contact temperature was lower, around 500°C, placing it in a safer operational zone with a much lower risk of spalling.

| Finishing Stand | Strip Entry Temp. (°C) | Peak Roll Contact Temp. (°C) | Spalling Risk |

|---|---|---|---|

| F1 | ~1010 | ~580-600 | High |

| F2 | ~970 | ~525 | Moderate |

| F3 | ~1000 | ~555 | High |

| F4 | ~950 | ~500 | Low |

Countermeasures Against Oxide Film Spalling

The field study confirmed that the high transient temperature in the bite zone is the primary driver of excessive oxide film growth. Therefore, the countermeasures focused on aggressively cooling the roll and strip surfaces at the critical moments.

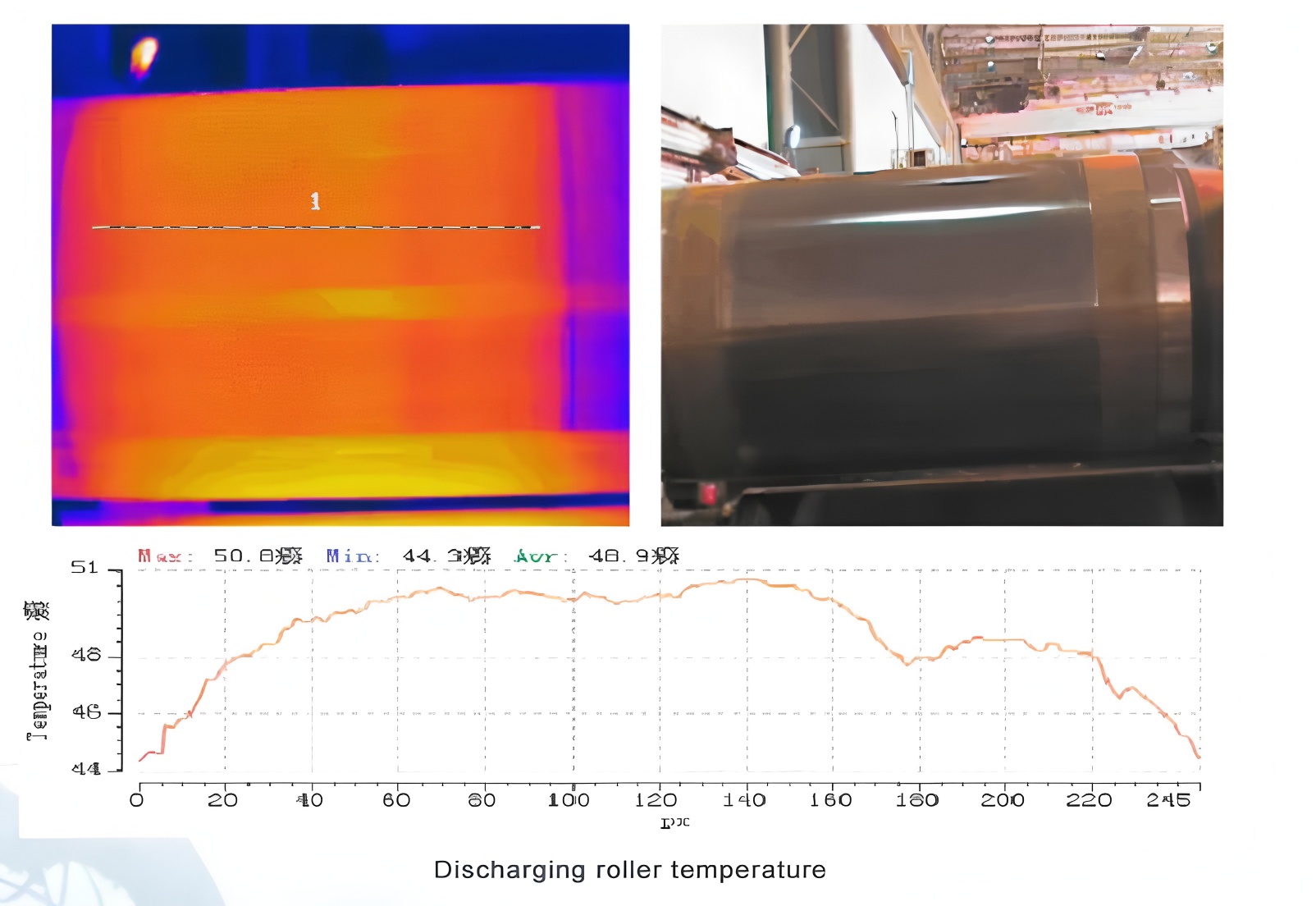

1. Increasing Inter-Stand Cooling Water (F2 & F3 Stands)

For the F2 and F3 stands, which showed the highest risk, the strategy was to increase the cooling water directed at the strip-roll interface. This was achieved by modifying the existing rolling oil and water system, adjusting header angles to spray directly into the bite zone. A series of progressive adjustments were made:

| Step | Action | Pressure (MPa) | Flow Rate (L/min per stand) | Avg. Roll Temp. (°C) | Result |

|---|---|---|---|---|---|

| 1 | Baseline (Rolling oil water only) | 0.4 | 96 | ~66 | Ineffective, spalling occurred. |

| 2 | Connected to roll cooling system | 1.2 | 192 | ~61 | Improvement, spalling reduced. |

| 3 | Increased nozzle flow | 1.2 | 240 | ~56 | Good condition, no spalling. |

| 4 | Final optimization | 1.2 | 480 | ~49 | Excellent condition, stable operation. |

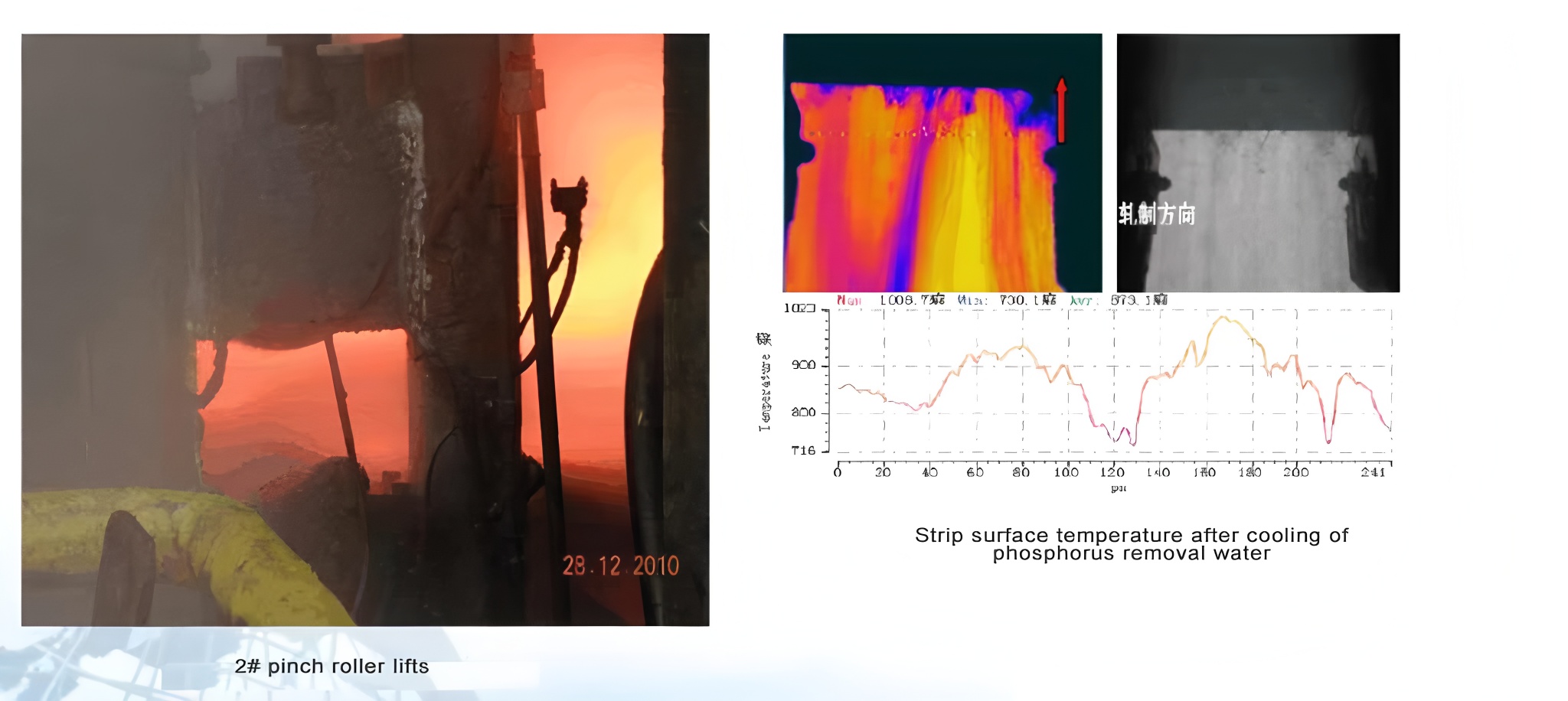

2. Utilizing Descaling Water to Cool the Strip Surface (F1 Stand)

The F1 stand lacked the modified cooling pipes. Given its proximity to the Finishing Scale Breaker (FSB) descaling box, an innovative solution was devised. After the steel strip was threaded, the FSB2# pinch roller was lifted, allowing the high-volume descaling water to continuously cool the strip surface just before it entered the F1 stand. This pre-cooling measure successfully reduced the strip surface temperature from 1010°C to approximately 950°C, thereby lowering the peak contact temperature on the F1 roll to below the critical threshold.

Effect Verification and Conclusion

The implementation of these targeted cooling strategies yielded immediate and significant results. The incidence of oxide film spalling was drastically reduced, and consequently, the number of temporary roll changes plummeted, restoring stability and efficiency to the production line.

In conclusion, the key findings and takeaways from this study are:

- Temperature is the Critical Factor: The primary cause of oxide film thickening and spalling on HSS rolls is the transient surface temperature exceeding 600°C during the bite.

- Dual-Stress Mechanism: Spalling is a result of the combined effect of thermal stress (from high temperature) and mechanical stress (from rolling force), which initiates and propagates microcracks.

- Targeted Cooling is Effective: Controlling the temperature at the precise moment of contact between the roll and the strip is the most effective way to prevent spalling.

- High-Pressure, High-Flow Solution: By applying high-pressure (1.2 MPa) and high-flow (up to 480 L/min) cooling water directly to the contact interface, the roll surface temperature can be kept in a safe operating range, effectively preventing oxide film spalling and ensuring the longevity and performance of high-speed steel rolls.