Types of Cast Iron Rolls and Manufacturing Overview

Classification by Manufacturing Process:

A roll with a white iron surface layer (matrix + carbide) formed by the chilling effect of a metal mold is referred to as a chilled cast iron roll.

When the same method is applied but with appropriately higher carbon content in the molten iron, resulting in a mottled structure (matrix + carbide + graphite), the roll is termed indefinite chilled cast iron roll. This indicates the absence of a distinct boundary in the chilled layer on the fracture surface.

Using sand-lined metal molds and further increasing carbon content produces a roll with a coarse mottled structure, known as a semi-chilled cast iron roll.

In all the above types, if the graphite is spheroidal, the roll is classified as a ductile iron roll. The term “composite” is added for compound cast rolls.

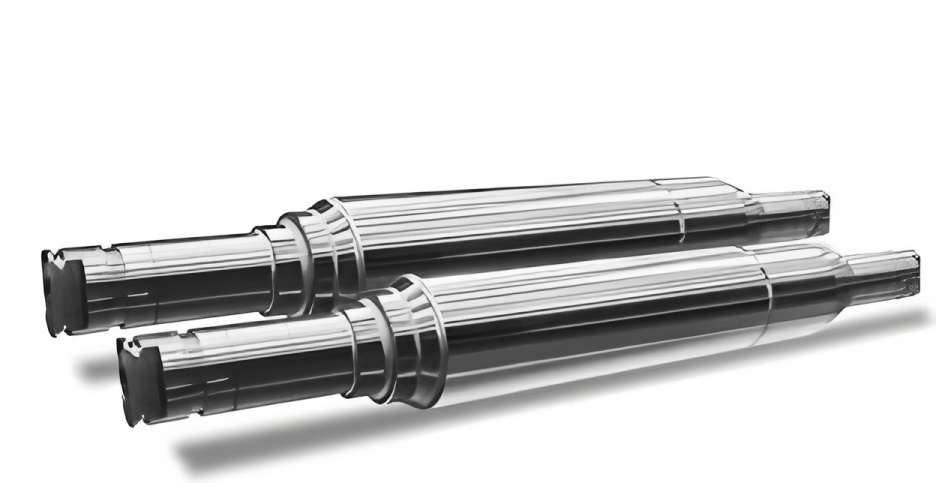

Professional Cast Iron Roll Manufacturer

Established in 2007, HANI GROUP specializes in producing a wide range of metallurgical rolls for hot and cold strip mills, section steel mills, bar mills, and high-speed wire rod mills.

The company occupies an area of 100,000 square meters, equipped with two complete production lines for cast and forged steel rolls. Facilities include machining workshops, product R&D centers, testing laboratories, training centers, office buildings, and other supporting infrastructure, all set within a well-maintained environment.

HANI has supplied products to top global steel manufacturers such as ArcelorMittal, TATA Steel, and EZZ Steel. The company also provides long-term OEM services for industry leaders including Concast and Danieli.