Analysis of Transverse Cracks in Backup Roll Forgings

Analysis of Transverse Cracks in Backup Roll Forgings Cracking remains a significant challenge affecting forging production development and product quality, representing a key research focus

Analysis of Transverse Cracks in Backup Roll Forgings Cracking remains a significant challenge affecting forging production development and product quality, representing a key research focus

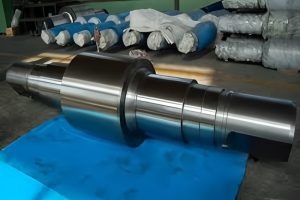

Abstract: Macro-etching, metallographic examination, scanning electron microscopy, and energy spectrum analysis were employed to investigate the fracture surface of a failed backup roll from a

From iron ore to finished steel, the material undergoes a series of complex processes to produce different categories. Hot-rolled steel coils and cold-rolled steel coils

PRE-INSTALLATION PREPARATION Roller Inspection Examine roller surfaces for defects including bumps, scratches, and pitting Address surface imperfections that could transfer to finished products Verify neck

DAILY INSPECTION Visual Inspection Examine roller surfaces before and after each operation Identify wear patterns, scratches, pitting, or corrosion damage Address minor scratches promptly with

Process Characteristics of Hot Rolling, Cold Rolling and ESP Steel Coils Reasonable Setting and Control of Rolling Parameters Accurate Rolling Force Calculation Calculate rolling forces

IMPROPER ROLLING PARAMETER SETTINGS Excessive Rolling Force Arbitrarily increasing rolling force without considering material properties and roll capacity Causes pressure exceeding design limits, leading to

PERFORMANCE IMPROVEMENTS Surface Quality Assurance Regular cleaning removes dust, metal chips, and oil contaminants Prevents surface defects like scratches and pitting on finished strips Maintains

CORRECT OPERATION AND USAGE Optimal Rolling Parameter Control Rolling Force Management Precisely regulate rolling force based on strip material, thickness, and width specifications Prevent excessive

MAINTENANCE CATEGORIES Backup roll maintenance is categorized into daily, regular, and special case processing. Daily maintenance includes surface cleaning, lubrication system checks, and operational monitoring.

All contents of this website are copyrighted by HANI GROUP and may not be reproduced in any form without permission.

We would be happy to help and advise if you have any questions or inquiries.